China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of automated equipment for medical devices. The company boasts a team of experts dedicated to the research and development of medical equipment. By adopting advanced technology, we have replaced traditional manual operations, achieving a level of sophistication on par with international counterparts. Guided by the principles of high technology, superior quality, and zero-defect service, we are committed to providing you with top-tier equipment and exceptional support.

Functions of Syringe Molds

Design and Manufacturing Syringes: Raw materials are shaped into standard or custom syringes through molding or other forming methods.

Ensuring Quality Consistency: Scientifically designed molds produce syringes with stable dimensions and uniform quality.

Improving Production Efficiency: Mass production techniques are used to accelerate syringe manufacturing.

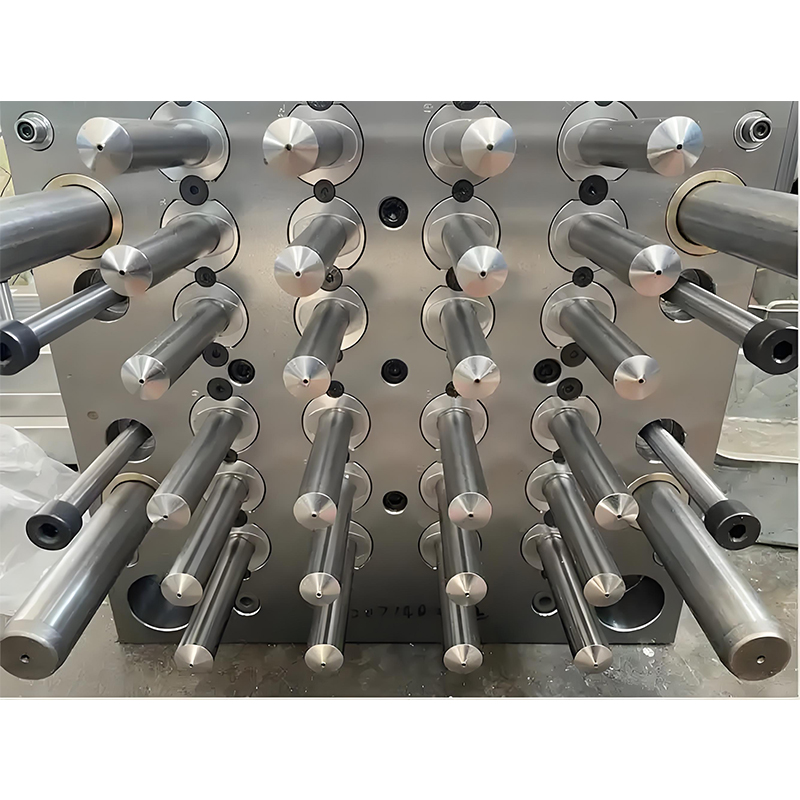

Syringe Mold Structure

Syringe molds typically consist of the following components:

Upper Die and Lower Die:

The upper and lower dies work together to form the closed structure of the syringe.

Making the material into the shape of the needle and cartridge through molding and other processes.

Core Holder:

Secures the core component of the mold, ensuring it does not move or deform during processing.

Commonly used to secure the position of cartridges or other critical components.

Guide Block:

Used to locate and secure the relative position of the upper and lower dies, ensuring accuracy during the molding process.

Spotting Pin:

Helps secure the mold during the molding process, preventing shifting or deformation. Flow Channel Design:

Ensures uniform material flow during the cooling process, avoiding problems such as bubbles and cracks.

Steps for Using a Syringe Mold

Material and Tool Preparation

Prepare raw materials (such as metal or plastic), die-casting molds, or investment casting molds.

Prepare tools and equipment, such as a molding press and parting table.

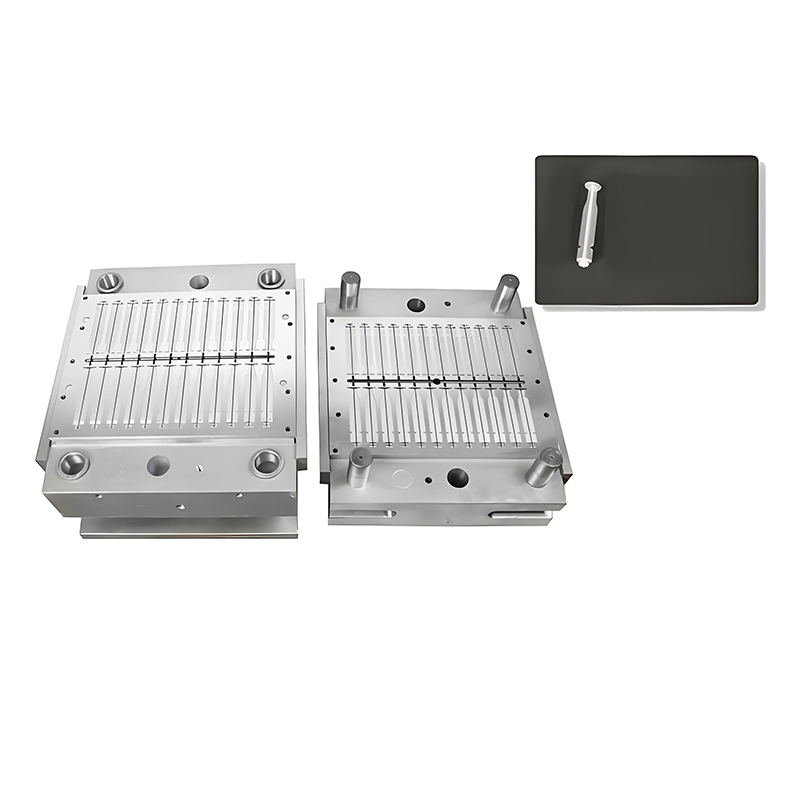

Design and Prototype Mold

Use computer-aided manufacturing (CAM) software to create a 3D model of the syringe mold.

Produce a mold prototype based on the design requirements and perform necessary testing and adjustments.

Mold Manufacturing

Use processes such as compression molding or investment casting to shape the raw material into the desired syringe shape.

During the mold manufacturing process, parameters such as pressure and temperature must be adjusted to ensure product quality and consistency.

Parting and Calibration

Separate the completed mold into the upper and lower molds, and calibrate each part to ensure accurate dimensions and position.

Clean and lubricate the mold to prevent problems such as eccentricity and leakage during processing. Syringe Production

Using known good molds, the formed syringes are fed into the assembly line, completing the final syringe manufacturing process.

Quality Inspection

Production syringes are inspected for dimensions, appearance, and sealing properties to ensure they meet standard requirements.

Based on the test results, the mold is repaired or replaced as necessary.

Applications of Syringe Molds

Medical Industry:

Manufacturing syringes for infusions, vaccinations, and other applications.

Highly customized to meet diverse customer needs (e.g., varying drug potency, needle length, etc.).

Industrial Applications:

Manufacturing syringes for other industrial applications, such as oil extraction and chemical processing.

Manufacturing syringes of standard sizes and specifications to ensure consistent product quality.

Custom Manufacturing:

Designing and manufacturing syringe molds with unique shapes or functions based on customer requirements.

Suitable for medical devices, industrial tools, gift manufacturing, and other fields.

Syringe Mold Maintenance and Care

Regular Cleaning: Remove dust and debris from the mold to ensure that no foreign matter is introduced during processing that could affect product quality.

Lubrication and Maintenance: Properly lubricate the mold to reduce friction and extend its life. Replace damaged parts: Promptly replace mold parts damaged by wear or corrosion to ensure proper functioning of the mold.

Calibration and adjustment: Regularly inspect and adjust each part of the mold to ensure accurate dimensions and position.

English

English русский

русский Español

Español