China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

A Fully Automated Production Line for Needle-Free IV Connectors represents a major step forward in medical device manufacturing. These connectors are delicate, require high precision, and must meet strict quality standards. Traditional manual processes often involve labor-intensive steps, a higher risk of defects, and slower production cycles. Automation addresses these challenges by combining robotics, great control systems, and quality monitoring to deliver a consistent and reliable output.

A Fully Automated Production Line for Needle-Free IV Connectors is designed to optimize every stage of manufacturing. From component assembly to final inspection, automation significantly reduces cycle times. Robotic arms perform repetitive tasks faster than human operators, while conveyors and feeders maintain a continuous workflow. This uninterrupted production not only increases output but also allows manufacturers to meet tighter deadlines without overextending labor resources.

Automation also enables real-time monitoring of production. Sensors and software track performance metrics, helping operators detect bottlenecks or deviations before they impact output. For manufacturers handling high-volume orders, this proactive approach ensures a steady supply of products without unexpected delays.

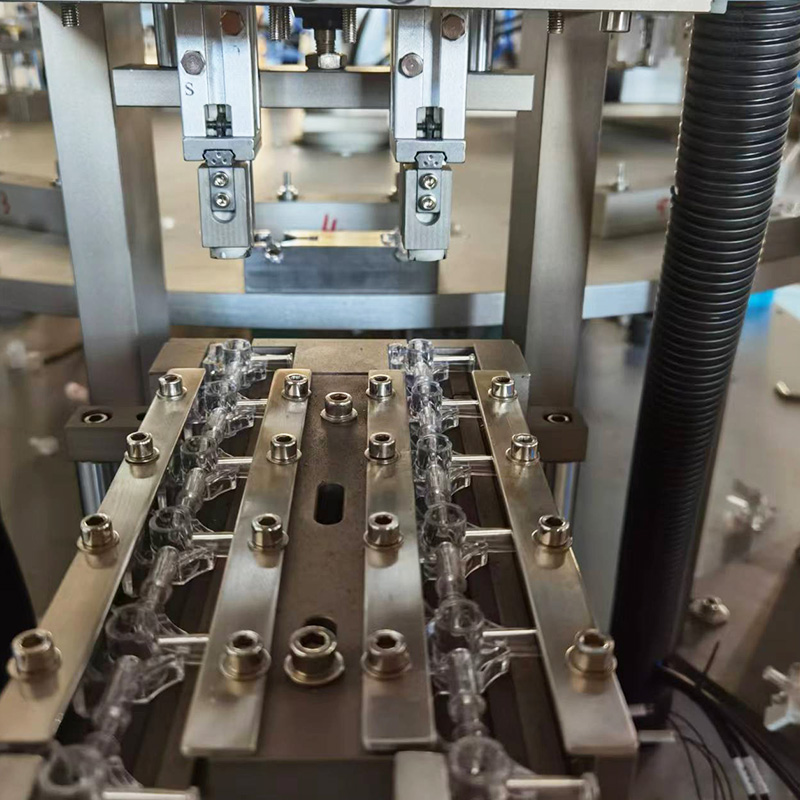

Precision is critical in producing needle-free IV connectors. Even minor errors can compromise device safety and functionality. A Fully Automated Production Line for Needle-Free IV Connectors incorporates great control systems capable of micron-level accuracy. These systems manage delicate assembly, sealing, and packaging processes with minimal human intervention, reducing the risk of error and ensuring consistent quality.

Vision inspection systems further enhance precision by verifying dimensions and detecting defects immediately. Any components that do not meet specifications are automatically removed or corrected, maintaining a high-quality standard throughout the production process.

Medical devices often involve diverse materials, from plastics to sensitive biomaterials. A Fully Automated Production Line for Needle-Free IV Connectors is versatile enough to handle these variations. Modular design allows customization of the workflow, integrating processes such as cutting, welding, or dispensing depending on product requirements.

By automating repetitive and labor-intensive tasks, a Fully Automated Production Line for Needle-Free IV Connectors reduces the need for large production teams. Operators can focus on oversight and process improvement instead of manual assembly. Over time, labor cost savings and improved efficiency make automation a practical investment, particularly for manufacturers scaling production or meeting growing demand.

High-quality standards are essential in the medical industry. A Fully Automated Production Line for Needle-Free IV Connectors integrates inspection and control mechanisms at each stage. Automated vision systems detect deviations in shape, size, or assembly integrity. great algorithms can alert operators to inconsistencies in real time, preventing defective products from reaching the market.

Selecting a Fully Automated Production Line for Needle-Free IV Connectors involves evaluating precision, speed, and adaptability. Consider equipment with a modular design for future product variations, great vision systems for quality control, and robust control mechanisms for consistent output. A well-chosen system can improve overall productivity, reduce operational costs, and deliver reliable, high-quality connectors consistently.

A Fully Automated Production Line for Needle-Free IV Connectors offers a practical solution for modern medical device production. It improves efficiency, enhances precision, and supports high-quality output while lowering labor costs. Manufacturers seeking to streamline operations, maintain compliance, and meet growing demand can benefit from integrating automation into their production workflow.

English

English русский

русский Español

Español