China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of automated equipment for medical devices. The company boasts a team of experts dedicated to the research and development of medical equipment. By adopting advanced technology, we have replaced traditional manual operations, achieving a level of sophistication on par with international counterparts. Guided by the principles of high technology, superior quality, and zero-defect service, we are committed to providing you with top-tier equipment and exceptional support.

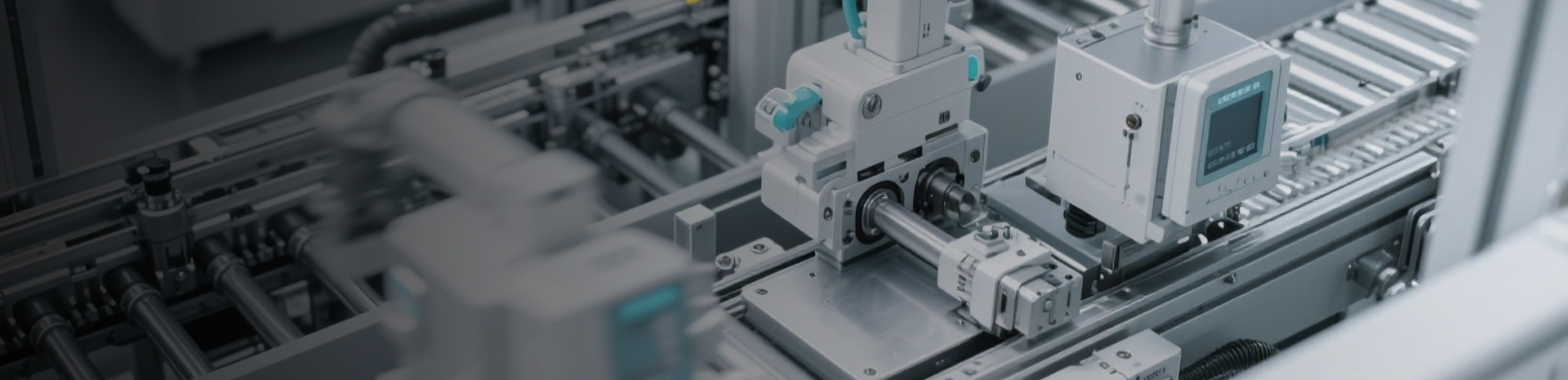

The Octagonal Heparin Cap Heat and Welding Automatic Assembly Machine is a good solution designed to streamline the production of medical-grade heparin caps through precise thermal bonding and assembly processes. Engineered with advanced automation technologies, this equipment delivers consistent quality, operational efficiency, and adaptability to meet the demands of modern pharmaceutical and medical device manufacturing.

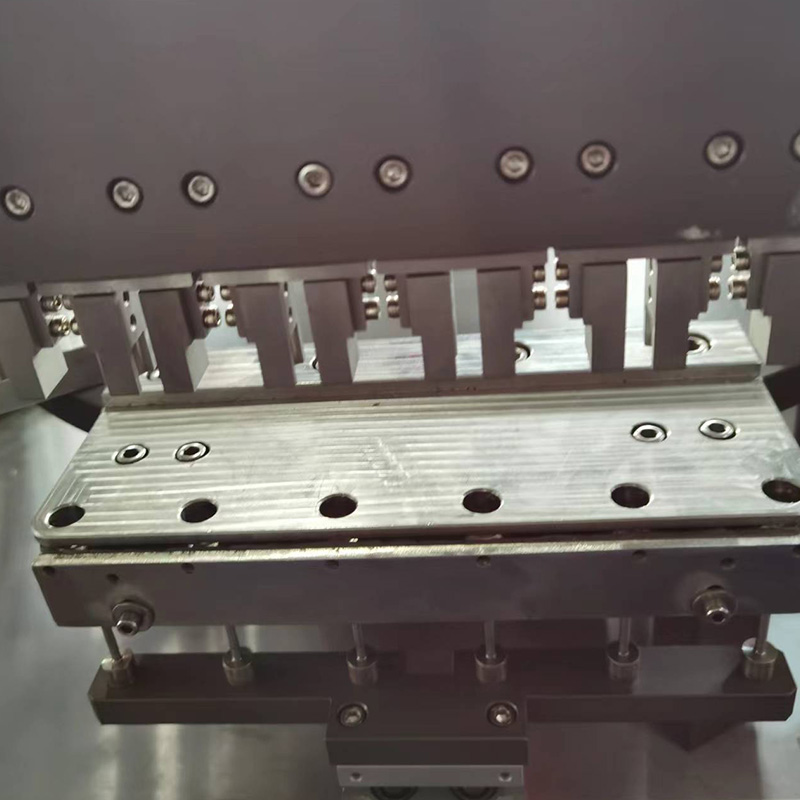

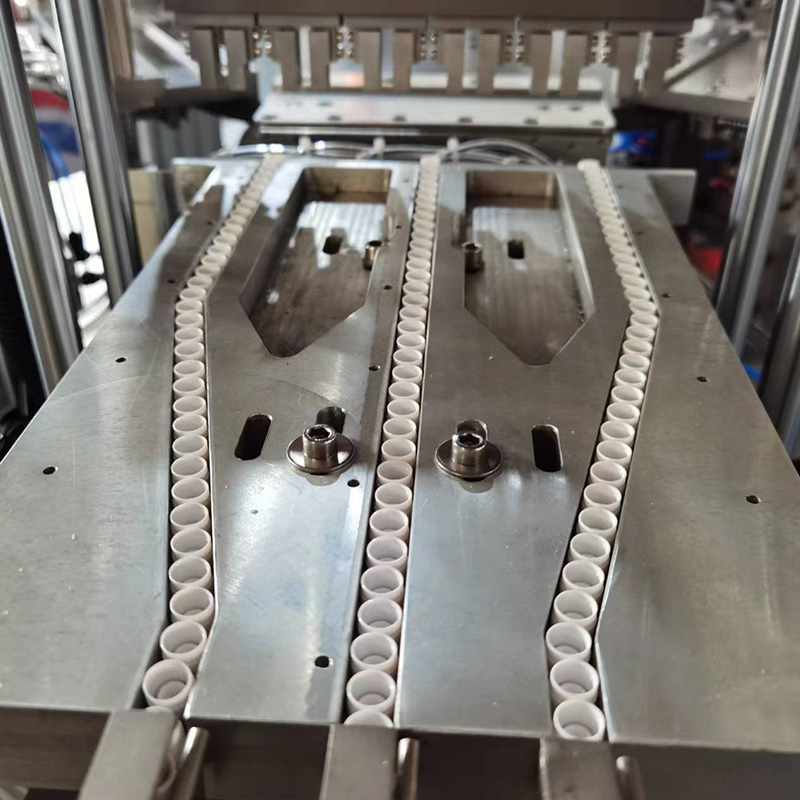

At its core, the machine specializes in the accurate assembly of octagonal heparin caps by leveraging controlled heat and welding techniques. The system ensures a secure bond between cap components while maintaining the structural integrity and functionality of the final product. Its modular design allows for seamless integration into existing production lines, offering flexibility in processing various cap sizes and configurations.

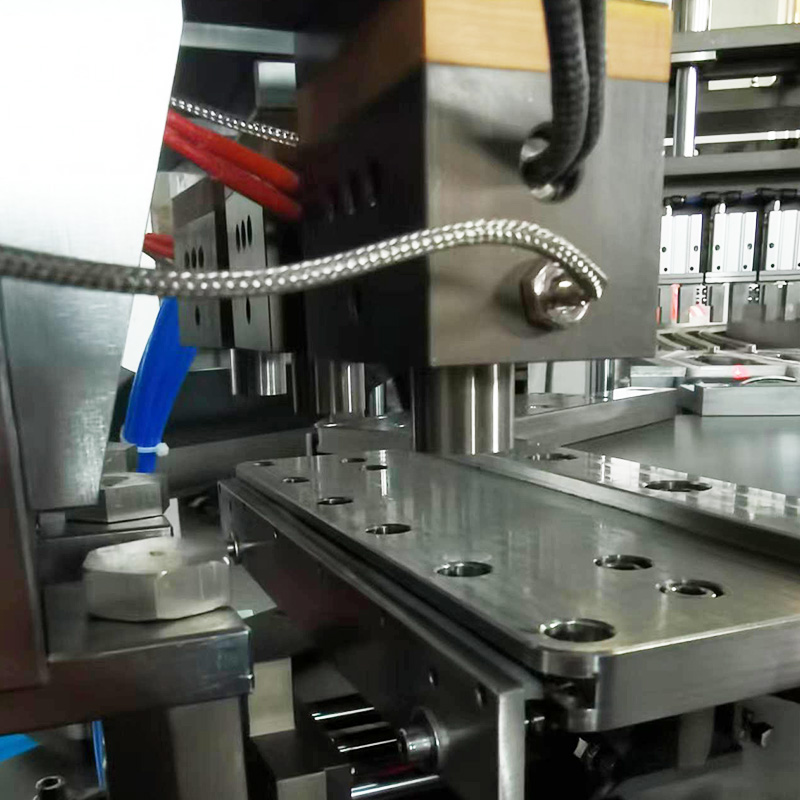

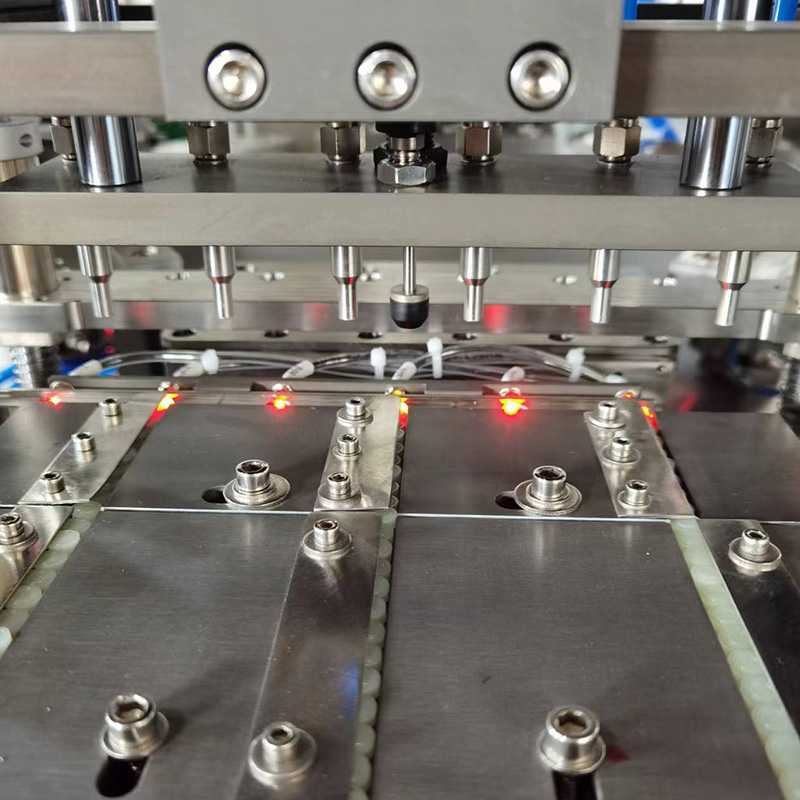

The assembly process is driven by good sensors and programmable logic controllers, which monitor and adjust critical parameters such as temperature, pressure, and alignment in real time. This level of precision reduces material waste, reduces defective outputs, and ensures uniform product quality. Additionally, the machine’s user-friendly interface simplifies operation, enabling technicians to program settings, manage production workflows, and conduct diagnostics with ease.

Safety and hygiene are important in medical manufacturing, and the machine incorporates features to meet stringent industry standards. Its enclosed design and easy-clean surfaces prevent contamination, while automated workflows reduce human intervention, further enhancing product safety.

Moreover, the Octagonal Heparin Cap Heat and Welding Automatic Assembly Machine is built for durability and reliability, with high-quality materials and robust construction ensuring longevity even under continuous operation. Its intuitive software interface supports rapid setup and customization, making it suitable for diverse production requirements.

By combining advanced automation, precision engineering, and compliance-focused features, this machine empowers manufacturers to achieve consistent product quality, reduce downtime, and scale operations seamlessly. Whether for prototyping or large-scale production, it serves as a dependable ally in the healthcare manufacturing sector, delivering innovative solutions for critical applications such as intravenous therapy and fluid delivery systems.

In summary, this automated assembly machine redefines efficiency and precision in heparin cap production, offering a reliable, adaptable, and future-ready solution tailored to the evolving needs of the medical device industry.

English

English русский

русский Español

Español