China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

Manufacturing medical devices demands high precision, strict quality control, and efficient processes. Among these, suction catheters require meticulous production due to their delicate structure and the critical applications in patient care. A Fully Automated Production Line for Suction Catheters offers a modern solution to meet these requirements, combining robotics, great control systems, and integrated quality checks. By implementing such automation, manufacturers can reduce production risks, optimize workflows, and maintain consistent product standards.

Automation not only addresses efficiency concerns but also enables medical device manufacturers to maintain competitiveness in an industry that increasingly relies on precision, speed, and compliance.

Efficiency is a core driver for adopting automation. Traditional manual production involves multiple repetitive tasks such as component assembly, material handling, and inspection. These steps are labor-intensive, time-consuming, and prone to human error.

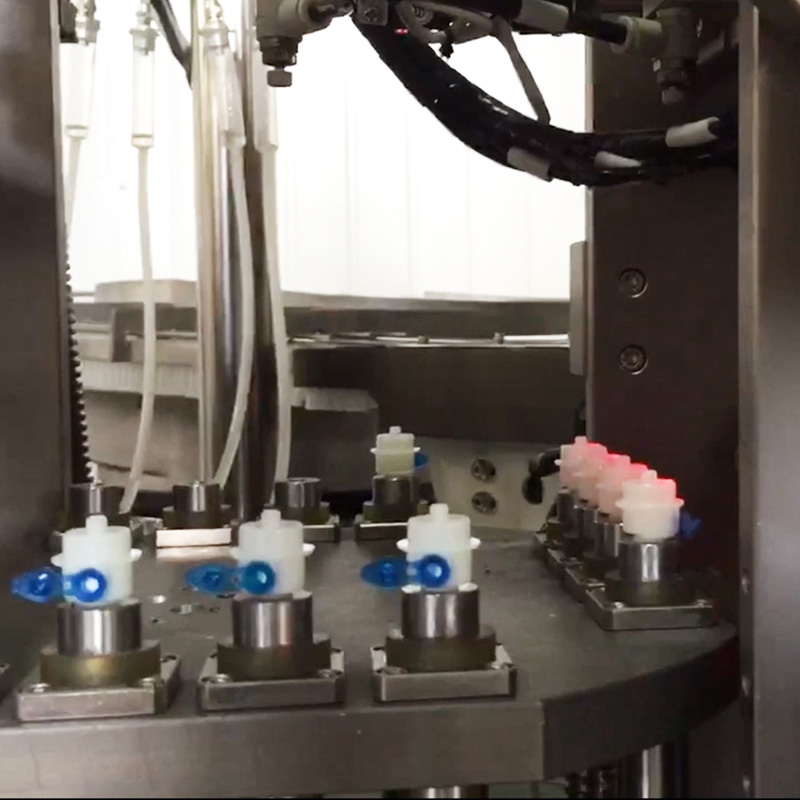

The Fully Automated Production Line for Suction Catheters replaces manual labor with high-speed robotic arms, synchronized conveyors, and automated dispensers. Production can continue uninterrupted, reducing idle time between operations. Real-time monitoring ensures any bottlenecks are immediately identified, allowing for timely adjustments.

Quality is non-negotiable in medical device production. Suction catheters must meet exact dimensional standards to function safely and effectively. The Fully Automated Production Line for Suction Catheters integrates robotic precision with great vision systems to monitor every stage of production.

Micron-level accuracy ensures that each catheter conforms to the required specifications. The system can detect tiny deviations that might go unnoticed in manual inspection, preventing defective products from reaching the market.

Automated quality checks also support regulatory compliance. In industries where FDA, ISO, or CE certifications are mandatory, maintaining precise records of inspections and defects is crucial. Automation allows manufacturers to document every stage efficiently, making audits simpler and more transparent.

Labor costs in medical device manufacturing are high. Skilled operators are expensive, and repetitive tasks can cause fatigue and errors. By introducing a Fully Automated Production Line for Suction Catheters, repetitive tasks are minimized, and human involvement shifts to goodvision, maintenance, and optimization roles.

This approach not only reduces labor costs but also frees staff to focus on higher-value activities such as process improvement, troubleshooting, and innovation. Over time, automation helps stabilize operational costs, especially in large-scale production environments.

Modern suction catheters are made from a range of materials, including plastics, elastomers, and sensitive biomaterials. Handling these materials manually increases the risk of contamination or damage.

A Fully Automated Production Line for Suction Catheters is designed for versatility. Its modular system can integrate processes like cutting, welding, dispensing, assembly, and packaging within one continuous workflow. Switching between materials or catheter types becomes easier, with minimal downtime and recalibration.

The medical device industry is evolving rapidly, and production efficiency, consistency, and quality are more important than ever. A Fully Automated Production Line for Suction Catheters addresses these needs by combining great robotics, precision control, and integrated quality assurance.

English

English русский

русский Español

Español