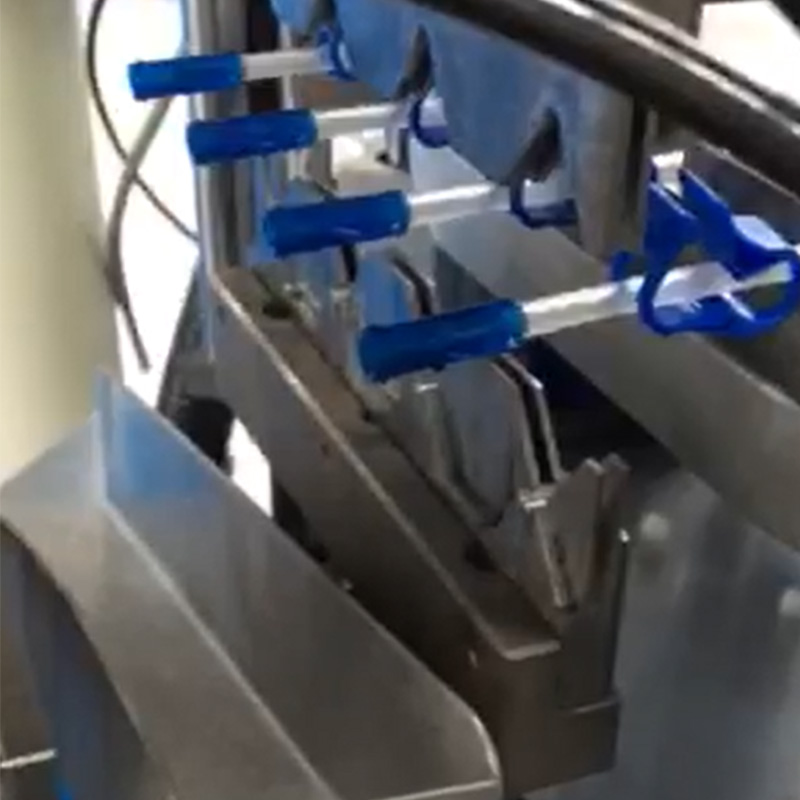

China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

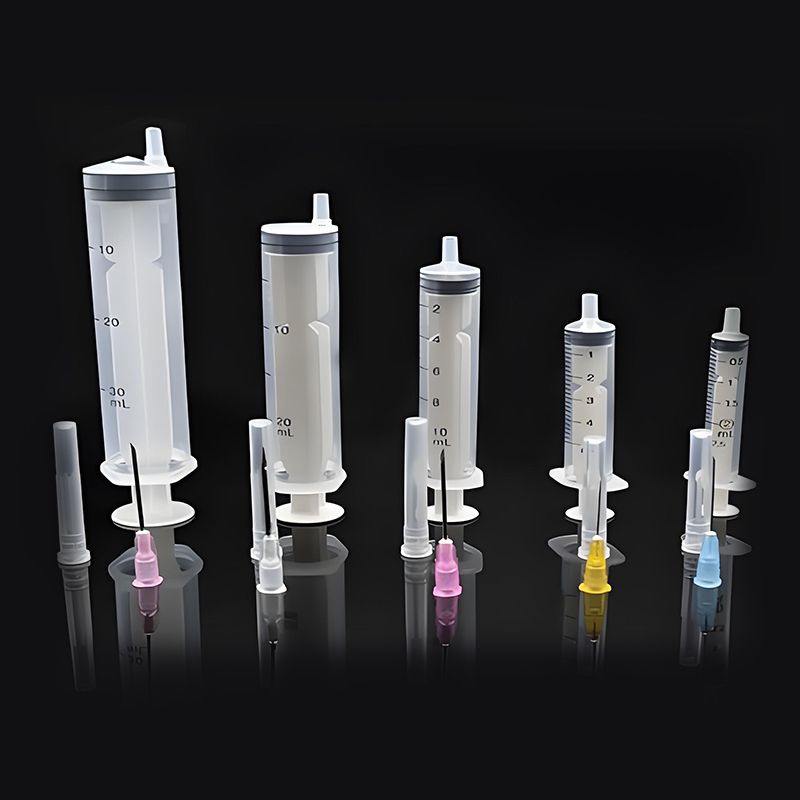

Medical plastic consumable products have become essential in hospitals, clinics, and laboratories. These items are not only practical and sterile but also highly reliable for a variety of medical applications. From catheters and tubing to containers and diagnostic tools, these products are central to maintaining efficiency, hygiene, and safety in healthcare settings. Working with a professional Medical Plastic Consumable Products Manufacturer ensures that each item meets stringent quality standards, providing peace of mind for medical staff.

Hospitals rely on these products daily, and their consistent availability can impact patient care, procedural efficiency, and operational costs. By understanding how medical plastic consumable products are designed and used, healthcare facilities can make informed decisions about sourcing and application.

Applications: How Medical Plastic Consumable Products Support Healthcare

Medical plastic consumable products cover a wide range of applications. One of the common uses is in medical tubing and catheters. Some catheters also include additional features such as sensors or balloons to enhance functionality for specific treatments.

Plastic containers and packaging are another critical application. Sterile containers are used to store surgical instruments, medications, and biological samples. Proper packaging ensures that the contents remain uncontaminated during storage or transport. Additionally, plastic materials act as protective barriers against moisture, oxygen, and environmental factors that could compromise medical supplies.

In laboratory diagnostics, medical plastic consumable products are equally important. Products such as microplates, test tubes, and petri dishes are widely used in analytical and testing procedures. Their reliability directly influences the accuracy of test results, supporting medical staff in making well-informed decisions regarding patient care.

Quality Considerations: Choosing a Reliable Manufacturer

Selecting a trusted Medical Plastic Consumable Products Manufacturer is crucial for maintaining quality and compliance. These manufacturers carefully select biocompatible plastics and use precise production techniques to ensure that products meet regulatory standards. Quality control processes include testing for sterility, material durability, and chemical resistance.

Manufacturers may also offer customization options for hospitals or labs with unique requirements. By partnering with a reputable manufacturer, healthcare providers can reduce the risk of defective products, maintain steady supply chains, and optimize operational efficiency.

Innovation and Trends: The Future of Medical Plastic Consumable Products

The field of medical plastic consumable products is evolving rapidly. Manufacturers are researching new materials and design improvements to enhance product performance and patient safety. For example, modern catheter designs may feature anti-microbial coatings or sensors that help reduce infection risk and improve treatment outcomes.

Packaging and containers are also evolving with improved sterilization methods, barrier technologies, and eco-friendly materials. Keeping up with these innovations allows healthcare providers to adopt products that improve workflow, maintain sterility, and support great medical procedures.

The Enduring Value of Medical Plastic Consumable Products

As materials science and production technologies great, medical plastic consumable products will continue to evolve, offering safer, more functional, and more efficient solutions for healthcare. By understanding the applications, quality standards, and innovations in these products, healthcare facilities can maintain high standards of patient care while optimizing operational workflows.

English

English русский

русский Español

Español