China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of automated equipment for medical devices. The company boasts a team of experts dedicated to the research and development of medical equipment. By adopting advanced technology, we have replaced traditional manual operations, achieving a level of sophistication on par with international counterparts. Guided by the principles of high technology, superior quality, and zero-defect service, we are committed to providing you with top-tier equipment and exceptional support.

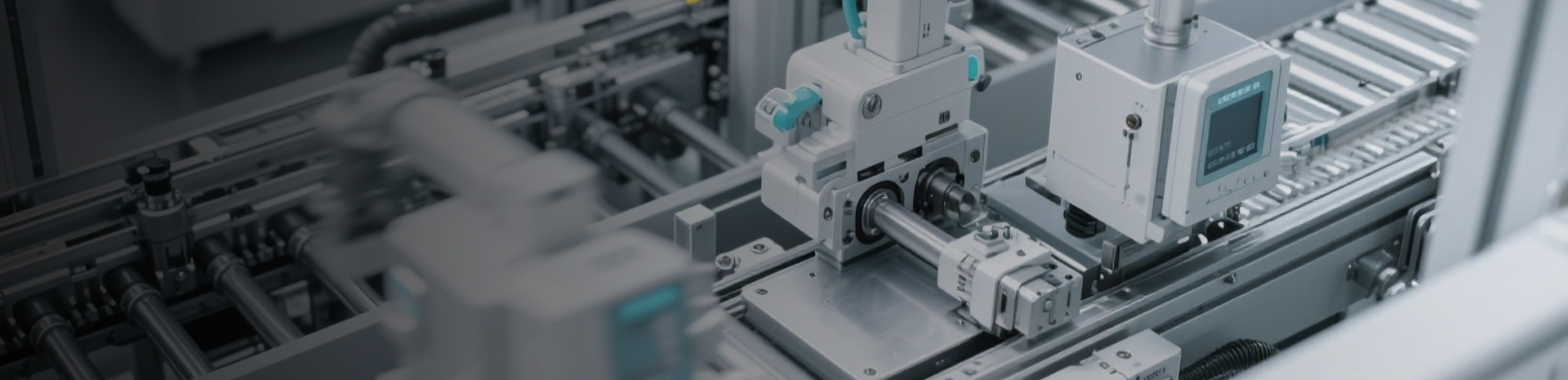

The Infusion Set Regulator Wheel Automatic Assembly Machine is a sophisticated piece of industrial equipment designed to streamline the assembly process of infusion set regulator wheels. This machine is engineered to enhance efficiency, accuracy, and productivity in manufacturing environments.

At its core, the machine features a highly advanced control system, accessible via a user - friendly interface on the control panel. The control panel is equipped with a clear display screen and intuitive buttons, allowing operators to easily set parameters, monitor the assembly process, and make real - time adjustments. Whether it's adjusting the speed of the assembly line, setting the torque for screw - fastening operations, or configuring the sequence of assembly steps, the control system provides precise and reliable control.

The machine is structured with a sturdy base and wheels for easy mobility, ensuring it can be conveniently repositioned within the production facility as needed. It has two large cabinets at the bottom, which not only provide a neat appearance but also offer ample storage space for tools, spare parts, and maintenance materials.

One of the key components of this machine is the automatic feeding system. It is designed to accurately and continuously supply the various components required for the assembly of the infusion set regulator wheel, such as the wheel itself, the regulator mechanism, and any necessary fasteners. This eliminates the need for manual component handling, reducing the risk of errors and increasing the overall speed of the assembly process.

The assembly area of the machine is carefully designed to ensure proper alignment and secure fastening of the components. Precision - engineered mechanisms work together to hold the parts in place while they are being assembled, ensuring that each infusion set regulator wheel is assembled to the high quality standards. Whether it's threading a screw, inserting a pin, or joining two parts together, the machine performs these operations with high accuracy.

In addition, the machine is equipped with safety features to protect both the operators and the equipment itself. These include warning labels, emergency stop buttons, and protective guards that prevent accidental contact with moving parts. The overall design of the Infusion Set Regulator Wheel Automatic Assembly Machine combines functionality, efficiency, and safety, making it a good choice for manufacturers looking to optimize their infusion set production processes.

English

English русский

русский Español

Español