China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of automated equipment for medical devices. The company boasts a team of experts dedicated to the research and development of medical equipment. By adopting advanced technology, we have replaced traditional manual operations, achieving a level of sophistication on par with international counterparts. Guided by the principles of high technology, superior quality, and zero-defect service, we are committed to providing you with top-tier equipment and exceptional support.

What are medical molds?

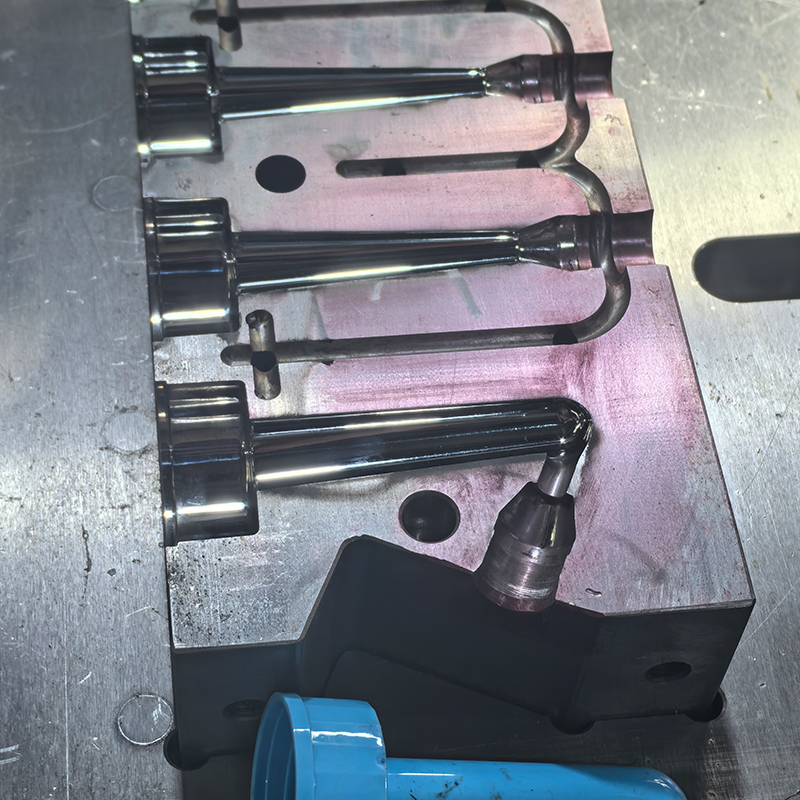

Medical molds refer to specialized mold systems used to manufacture medical devices and instruments. Their core function is to shape metal, plastic, or other materials into standardized shapes and sizes that meet medical requirements through molding processes such as injection molding and stamping.

Medical molds are widely used in the following areas:

Medical device production: such as surgical instruments, syringes, IV tubing, and prostheses.

Medical device manufacturing, such as ultrasonic scalpels and dental equipment.

Laboratory equipment: used for precise control and preparation of reagents in teaching and scientific research.

Features include high precision, high stability, compliance with human biological characteristics, and mass production capabilities, ensuring the safety and effectiveness of medical devices.

Types of Medical Molds

Depending on the application and manufacturing process, medical molds can be divided into the following main types:

Syringe molds:

Used for the production of disposable syringes, needles, and other medical devices.

Key function: Precisely control the amount and location of drug injection to avoid infection risks.

Infusion tube molds:

Used for the manufacture of IV tubes, droppers, and other medical devices for infusion of liquids. Features: Excellent sealing performance, suitable for long-term use.

Surgical Instrument Molds:

Used for the production of instruments such as scalpels, forceps, and suture cutters.

Requirements: High strength, corrosion resistance, and easy cleaning and disinfection.

Laboratory Equipment Molds:

Used for the manufacture of equipment for accurately preparing chemical reagents, such as constant temperature water baths and gas purification units.

Features: High-precision control and strong stability.

Custom Molds:

Design and manufacture non-standard medical devices based on customer needs.

Commonly used in the production of personalized medical devices.

Steps in Using Medical Molds:

Determine Requirements and Specifications

Define standard parameters for the medical device, such as size, shape, and material.

Determine the material type and performance requirements (such as biocompatibility and strength).

CAD Modeling and Design

Use computer-aided design (CAD) software for 3D modeling and design optimization.

Generate precise mold structure drawings based on the mold's functional requirements.

Mold Manufacturing

The mold body is produced using various molding processes, including injection molding, stamping, and forging. Select and process mold materials to ensure their performance meets requirements.

Drive Mechanism and Connection Design

Design and manufacture drive mechanisms (such as cylinders and servo motors) to control mold movement and loading.

Connect to the mold to ensure precise operation and stability.

Testing and Debugging

Perform mold performance tests, including strength and sealing tests.

Adjust mold design or drive mechanism operating parameters based on test results to optimize performance.

Manufacturing Medical Devices

Integrate molds into complete medical devices to ensure coordinated operation.

Conduct pilot production to verify device performance and safety.

Quality Control and Testing

Strictly test manufactured medical devices to ensure compliance with standard requirements.

This includes dimensional inspection, mechanical testing, and biocompatibility testing.

Maintenance and Care

Regularly inspect molds to ensure long-term stable operation.

Clean and lubricate key components to extend device life.

Applications of Medical Molds in Medical Applications

Manufacturing Disposable Medical Devices:

Such as syringes and IV tubing, ensure single-use to reduce the risk of secondary contamination. Medical Device Manufacturing:

Manufacturing high-precision medical devices such as ultrasonic scalpels and dental treatment devices.

Ensuring device stability and safety.

Laboratory and Teaching Equipment:

Providing precisely controlled dispensing systems for scientific experiments and teaching.

Enhancing experimental safety and accuracy.

Customized Medical Device Manufacturing:

Designing and manufacturing customized medical devices based on the needs of specific patients or hospitals.

Meeting personalized medical needs.

Medical Mold Maintenance and Care

Regular Cleaning and Disinfection

Clean the mold surface to ensure no residual dirt to prevent contamination of the medical device.

Sterilize using effective disinfectants to prevent microbial growth.

Lubrication and Maintenance

Properly lubricate key components (such as cylinders and drive motors) to reduce friction and extend service life.

Regularly check the effectiveness of the lubrication system.

Seal Inspection

Check the mold's sealing performance to ensure there are no leaks within the medical device.

Use specialized sealants or replace seals for optimal performance.

Drive Mechanism Calibration

Regularly calibrate the drive mechanism's operating parameters to ensure device accuracy and stability. Test and verify calibrated equipment.

Environmental Control

Ensure that molds and medical devices maintain appropriate temperature and humidity conditions during use.

Prevent extreme environments from affecting device performance.

Spare Parts Management

Regularly inspect and replenish spare parts, such as drive mechanisms and seals, to ensure proper device operation.

Promptly replace or repair damaged parts.

Summary

Medical molds play a vital role in medical device production. Through high-precision manufacturing and rigorous quality control, they ensure that medical devices are safe, reliable, and compatible with human biology. During use, attention to detail, including material selection, temperature control, standardized operating procedures, and equipment maintenance, is crucial to ensure device performance and patient safety.

English

English русский

русский Español

Español