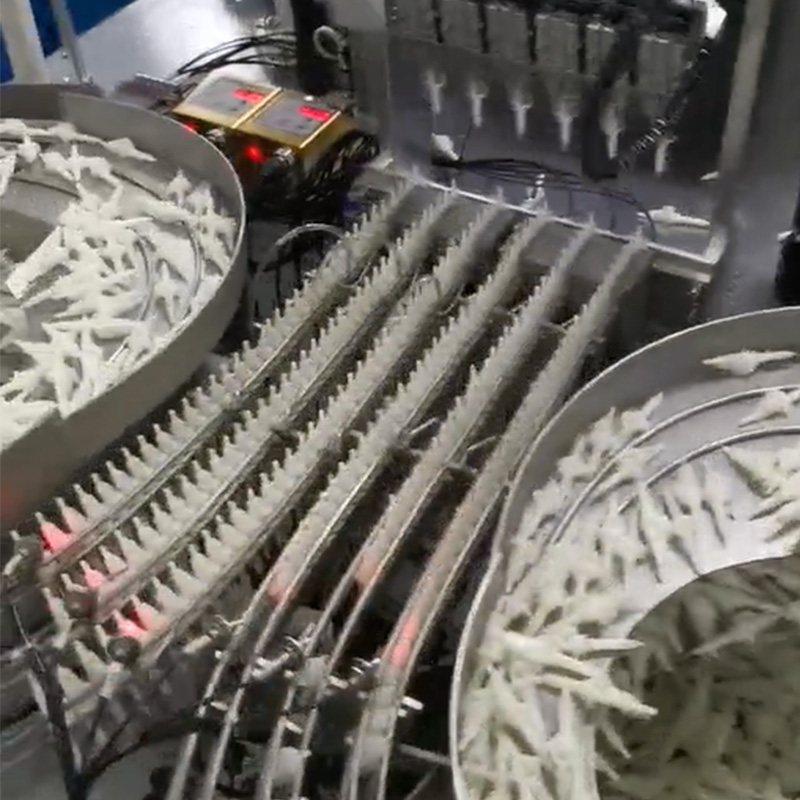

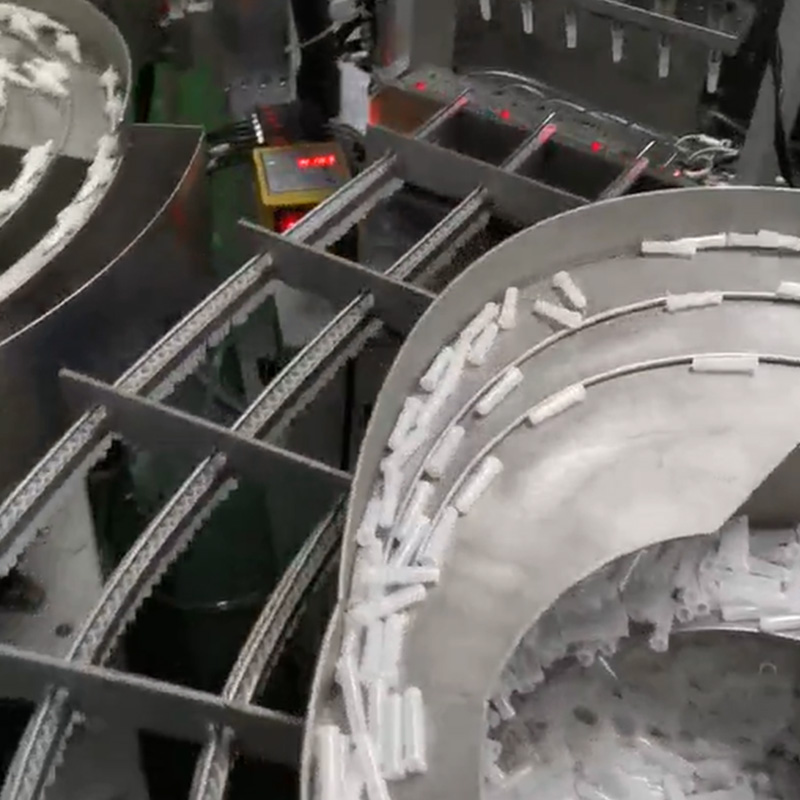

China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of automated equipment for medical devices. The company boasts a team of experts dedicated to the research and development of medical equipment. By adopting advanced technology, we have replaced traditional manual operations, achieving a level of sophistication on par with international counterparts. Guided by the principles of high technology, superior quality, and zero-defect service, we are committed to providing you with top-tier equipment and exceptional support.

This innovative medical device is engineered to enhance safety and efficiency in needle handling and pharmaceutical packaging applications. Designed with precision, it combines functionality with user-friendly features to address critical needs in sterile environments.

Key Components and Structure

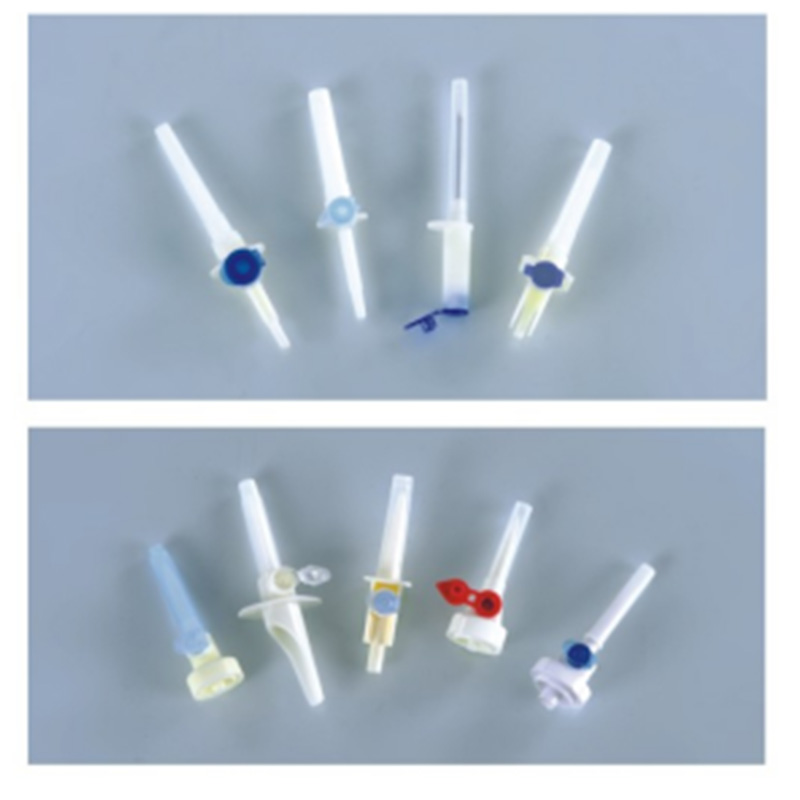

The product consists of a durable, lightweight plastic body shaped into a compact cover that seamlessly fits over standard needle bottles. Its breathable surface incorporates a specialized air filter system, ensuring airflow while maintaining sterility. The filter acts as a barrier against contaminants, safeguarding the integrity of medications or solutions stored within.

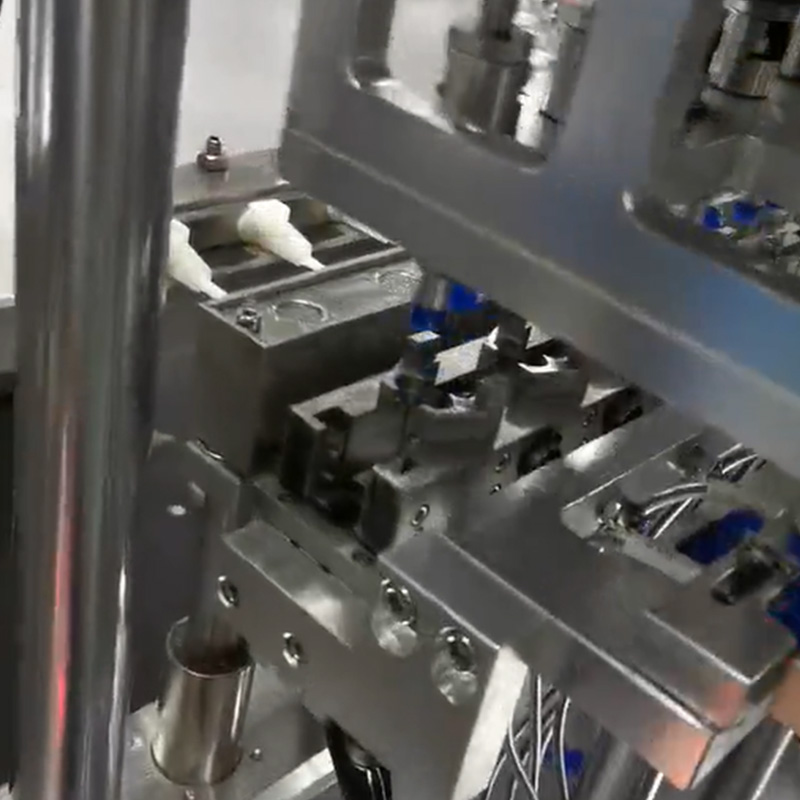

A central puncture device allows for quick and secure access to the bottle’s contents. This mechanism is ergonomically designed to minimize user error and reduce the risk of needlestick injuries. The puncture tip is reinforced to withstand repeated use while preserving sharpness for seamless penetration.

Operational Workflow

Sealing and Protection: The cover attaches securely to the bottle’s neck, creating an airtight seal reinforced by the filter. This step prevents external particles or pathogens from compromising the contents.

Controlled Puncture: When accessing the bottle, the user activates the puncture device with minimal force. The system ensures a single, clean puncture, reducing the chance of leakage or contamination.

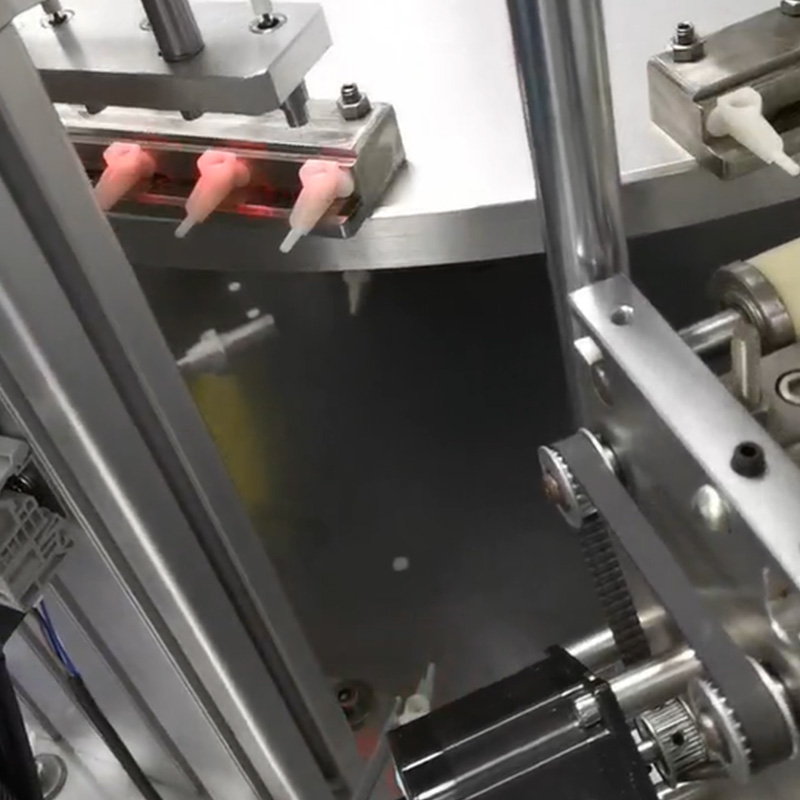

Efficient Workflow: Designed for high-volume settings, the device supports rapid deployment in automated or manual assembly lines, aligning seamlessly with production demands.

Material and Durability

Crafted from medical-grade plastic, the device offers good chemical resistance and longevity. Its smooth surface resists residue buildup, simplifying cleaning and maintenance. The puncture component is built to endure repeated use without degradation, ensuring consistent performance over time.

Application Versatility

Proper for vials, ampoules, or cartridges used in pharmaceuticals, biotech, or cosmetic industries, this device enhances safety across needle-based procedures. Its adaptability supports both single-use and multi-dose containers, making it a versatile solution for diverse applications.

With its seamless integration of airflow management, puncture precision, and hygienic design, this needle bottle cover elevates safety standards while optimizing operational efficiency. It serves as an essential tool for professionals seeking reliable, contamination-resistant solutions in critical healthcare and industrial environments.

English

English русский

русский Español

Español