China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

Medical device manufacturers today face increasing pressure to produce high-quality products efficiently while keeping costs under control. In this context, Medical Automation Equipment has emerged as a transformative solution. These systems use robotics, great sensors, and intelligent control software to automate complex manufacturing tasks, ensuring precision and reducing human error.

A prime example is the Fully Automated Production Line for Hemodialysis Circuit Consumables. This system integrates assembly, inspection, and packaging processes into a single, continuous workflow. By automating repetitive and delicate operations, manufacturers can maintain high-quality standards while scaling production to meet market demand.

Section 1: Enhancing Precision and Accuracy

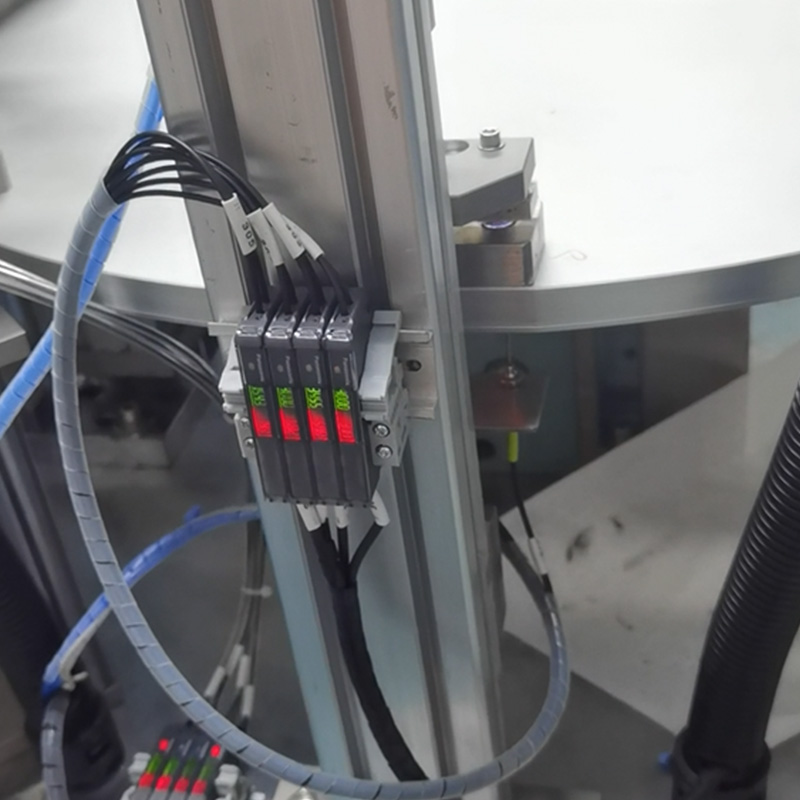

One of the biggest challenges in medical device manufacturing is achieving consistent precision. Even minor inconsistencies can affect patient safety, especially in hemodialysis circuits where flow accuracy and tubing integrity are critical. Medical Automation Equipment addresses these issues by incorporating robotic arms and vision-guided inspection systems.

For example, during the assembly of hemodialysis consumables, the equipment can align tiny connectors and tubing with micron-level accuracy. Each component is checked multiple times along the production line. The Fully Automated Production Line for Hemodialysis Circuit Consumables ensures that assembly, welding, and packaging meet strict quality standards, reducing defects and minimizing waste.

Automation not only improves precision but also enables real-time adjustments. If the system detects a misalignment or defect, it can automatically correct the issue or remove the item from the production line. This proactive approach significantly reduces the risk of faulty products reaching the market.

Section 2: Streamlining Production Efficiency

Labor-intensive processes in medical manufacturing can slow down production and increase costs. Repetitive tasks, such as tubing assembly, component placement, or packaging, are prone to human error and fatigue. By automating these steps, Medical Automation Equipment allows manufacturers to maintain a continuous, high-speed workflow.

The Fully Automated Production Line for Hemodialysis Circuit Consumables is designed to operate 24/7 with minimal human intervention. Its robotic arms and conveyor systems handle large volumes efficiently, while integrated sensors monitor every stage of production. This level of automation ensures that manufacturers can meet tight deadlines, respond to demand fluctuations, and optimize labor allocation.

In addition, the system collects production data in real time. Factory managers can analyze this data to identify bottlenecks, plan maintenance schedules, and further optimize the workflow. The combination of speed, consistency, and real-time analytics makes automation a key advantage in competitive medical manufacturing.

Section 3: Versatility and Adaptability

Medical device production often requires handling a variety of materials and components. Medical Automation Equipment is designed with modularity in mind, allowing manufacturers to adapt the system to different product lines. Whether working with plastics, metals, or delicate biomaterials, the equipment can be reconfigured quickly to meet changing production needs.

The Fully Automated Production Line for Hemodialysis Circuit Consumables demonstrates this adaptability by integrating multiple processes—cutting, welding, assembly, and inspection—into one workflow. Manufacturers can introduce new products or modify existing designs without major changes to the production setup. This flexibility reduces downtime and supports faster product development cycles.

The Fully Automated Production Line for Hemodialysis Circuit Consumables exemplifies how targeted automation can transform complex manufacturing processes into smooth, reliable operations. Companies leveraging these systems can reduce labor-intensive tasks, minimize errors, and maintain a competitive edge in an evolving market. Automation is no longer just an option—it is becoming a core component of modern medical device production strategies.

English

English русский

русский Español

Español