China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

A clear, stable production process is one of the core needs of medical manufacturers. When medical brands develop tubing, catheters, packaging parts, or diagnostic consumables, they usually face challenges such as demanding accuracy, pressure on delivery timelines, and the need for reliable materials. This is where a professional Medical Plastic Mould Factory plays an important role. A well-built Medical Plastic Mould supports smooth manufacturing, reduces unexpected defects, and helps your team focus on product innovation rather than troubleshooting.

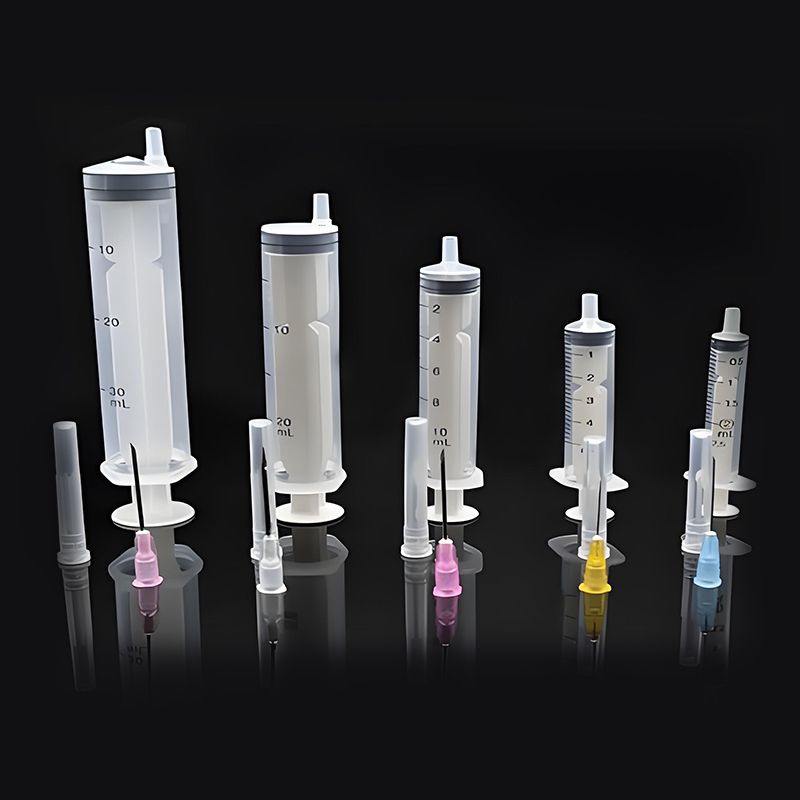

Medical plastic products require consistent structures, smooth surfaces, and predictable performance, especially when used in sensitive applications. Medical tubing and catheters, for example, must maintain a stable inner diameter so fluids can pass without blockage. Small changes in wall thickness or surface finish can affect how the device behaves inside the human body. A carefully engineered Medical Plastic Mould allows these parts to be produced with even geometry and repeatable results. For factories supplying items like infusion sets, blood-related devices, or urinary catheters, this kind of mould accuracy supports a smoother downstream assembly process.

Our Medical Plastic Mould Factory focuses on mould solutions for tubing, connectors, caps, and functional components used in hospitals and labs. Many customers share the same concerns: unstable fit between parts, increased scrap rate, or inconsistent delivery schedules. These issues usually come from older or poorly maintained moulds with limited precision. When such moulds are upgraded, the entire production line becomes more predictable. Teams experience fewer interruptions, and material waste is reduced. It also becomes easier for purchasing teams to control overall cost because the process no longer fluctuates.

Containers for surgical tools, medication storage, sample preservation, and sterile transport require clean surfaces and steady sealing structures. When the mould quality is not stable, lids may not match well, edges may not form cleanly, or the product may have small defects that affect its usability. Our Medical Plastic Mould Factory works on these details by refining gate positions, venting, and cooling systems so that each cycle produces products closer to your target specifications.

Diagnostics is another field that depends heavily on tight tolerances. Labware such as microplates, petri dishes, and test tubes must maintain dimensional accuracy so instruments can read them correctly. Even a small distortion in shape can affect experimental results. A strong Medical Plastic Mould helps keep these consumables uniform. With proper mould steel, controlled temperature channels, and clean machining, the final products support reliable lab operations.

Below are key points customers often care about when choosing or upgrading a Medical Plastic Mould:

- Stable Part Dimensions

Medical projects often involve thousands or millions of repeated pieces. Dimensional drift creates downstream problems such as leakage, misfits, or measurement errors. A well-built mould provides a steady foundation for large-volume production.

- Smooth Surface Quality

For tubing and catheters, even small imperfections can affect fluid flow. A polished cavity and good mould maintenance help deliver smooth surfaces without extra manual work.

- Material Compatibility

Medical plastics—such as PP, PE, PVC, and medical-grade elastomers—require specific flow conditions. A professional Medical Plastic Mould Factory designs runners and gates to match these materials, improving overall process stability.

- Clean Production Support

Many medical parts enter clean environments. Mould design choices, such as internal airflow control and reduced dead corners, help maintain cleaner production spaces.

As medical applications continue to evolve, the role of an experienced Medical Plastic Mould Factory becomes even more valuable. From medical tubing to lab consumables and sterile packaging, a dependable mould helps products move smoothly from concept to large-scale production. If your team is looking for more predictable results and fewer production challenges, upgrading or customising a Medical Plastic Mould may be the next practical step.

English

English русский

русский Español

Español