China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The medical industry is continuously evolving, with technological advancements driving improvements in efficiency, accuracy, and safety. Among the many innovations that have reshaped the sector, syringe assembly machines play a critical role in ensuring the quality and reliability of syringes used in healthcare settings worldwide. As demand for medical products rises, so does the need for more efficient production methods. Syringe assembly machines, syringe assembly equipment, and syringe assembly filling device assembly machines have emerged as crucial components in the manufacturing process, streamlining operations and meeting the rigorous demands of modern healthcare.

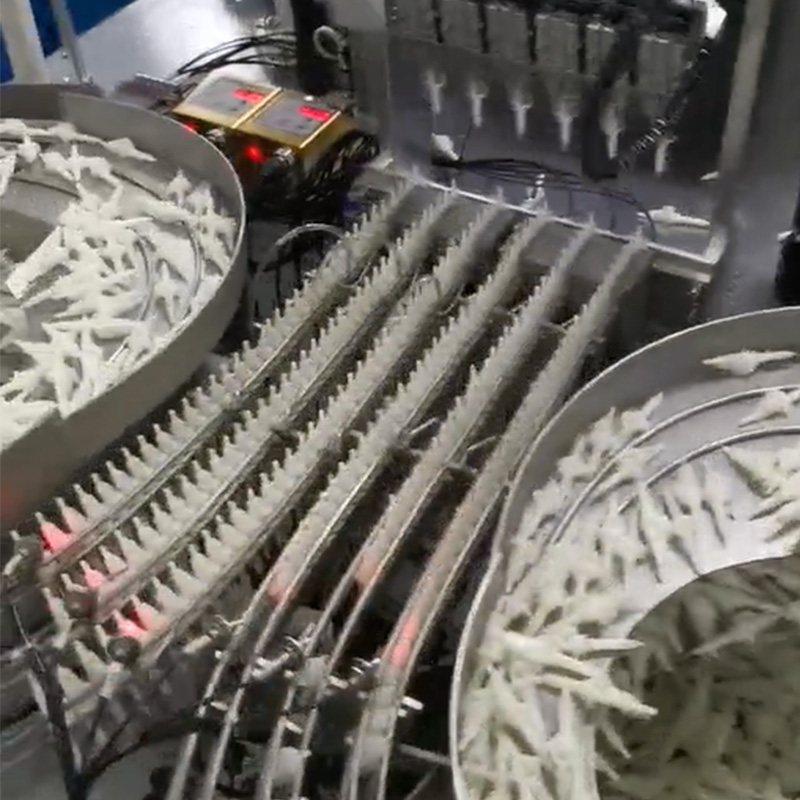

The process of syringe production has traditionally been labor-intensive, requiring highly skilled technicians to assemble each part with precision. However, with the development of syringe assembly machines, manufacturers are now able to automate much of this process, significantly reducing human error while enhancing output speed. These machines are designed to handle the delicate and complex task of assembling syringes by efficiently combining the various components, such as the barrel, plunger, needle, and cap, in a controlled and systematic manner.

Syringe assembly equipment comes in various forms, each tailored to different stages of the syringe production process. Some machines focus on the assembly of the syringe body, while others are designed for more specialized tasks, such as filling the syringes with medication. The integration of advanced technologies, including robotics and precision engineering, allows these systems to work at high speeds while maintaining a high degree of accuracy. This is especially important in the production of medical syringes, where even a slight deviation can compromise the safety and efficacy of the product.

One of the significant developments in the syringe manufacturing industry is the syringe assembly filling device assembly machine. These machines are specifically designed to accurately and efficiently fill syringes with the required dosage of medication. In the past, filling syringes was a manual process, often involving significant human labor and the risk of contamination. Today, the syringe assembly filling device assembly machine ensures that each syringe is filled precisely according to its specifications, minimizing the chance for errors and improving the overall quality control of the production line.

The benefits of syringe assembly machines are evident not only in the production speed but also in the overall quality of the syringes produced. With the automation of the assembly process, manufacturers can achieve consistent results, ensuring that each syringe meets the strict standards required by regulatory bodies. This is particularly important when it comes to medical devices, as any inconsistency in the manufacturing process can to serious consequences for patients.

Another advantage of syringe assembly equipment is its ability to handle a wide variety of syringe types. Whether producing standard syringes, insulin pens, or specialized syringes for vaccines, these machines can be adjusted to accommodate different sizes, shapes, and configurations. This flexibility is essential in a market that demands a diverse range of syringe products to meet varying medical needs. As the demand for vaccines and injectable medications continues to grow, the role of syringe assembly machines in ensuring the timely and accurate production of these essential tools becomes more crucial than ever.

The introduction of syringe assembly filling device assembly machines has also had a significant impact on cost efficiency. While the initial investment in these machines can be substantial, their ability to automate labor-intensive tasks results in significant savings over time. Manufacturers can reduce the number of employees required for manual assembly and filling, allowing them to allocate resources to other areas of production. Moreover, by increasing production capacity and reducing the risk of human error, these machines help to ensure that manufacturers can meet the ever-growing demand for medical syringes.

As the global demand for medical syringes continues to rise, the need for advanced syringe assembly equipment will only increase. Innovations in automation, robotics, and precision engineering will continue to drive improvements in syringe production, enabling manufacturers to meet the high standards required by healthcare providers. The integration of syringe assembly machines and syringe assembly filling device assembly machines into the production line is no longer a luxury but a necessity for manufacturers looking to stay competitive in a rapidly changing market.

In conclusion, syringe assembly machines and syringe assembly equipment are revolutionizing the way syringes are produced, offering numerous benefits in terms of speed, accuracy, and cost efficiency. The introduction of syringe assembly filling device assembly machines has further enhanced these advantages by ensuring precise filling of syringes with minimal risk of contamination. As the healthcare industry continues to evolve, these machines will play an increasingly vital role in ensuring that syringes are produced to the standards, ultimately benefiting patients and healthcare professionals alike.

English

English русский

русский Español

Español