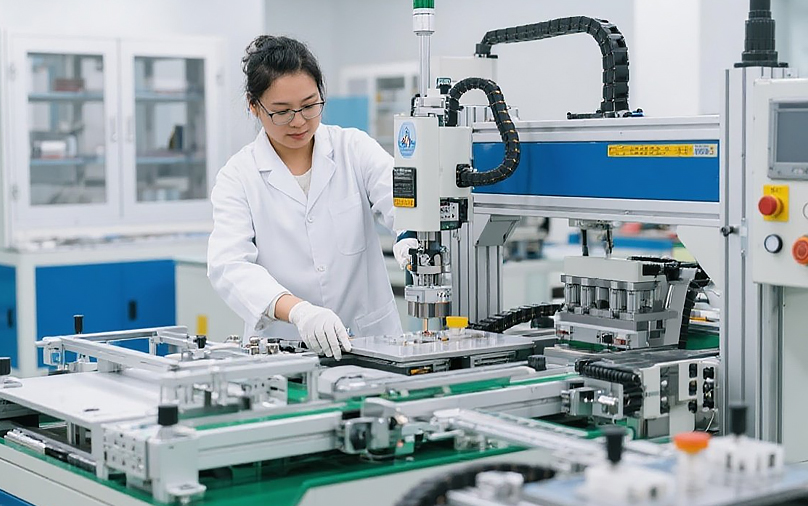

China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

In the rapidly advancing field of medical device manufacturing, the need for efficient and precise equipment is paramount. One such critical machine is the Types of Suction Catheter Assembly Machine, a pivotal tool in the production of suction catheters. These machines not only streamline the assembly process but also ensure that medical-grade components meet strict regulatory standards. With a growing emphasis on automation and precision in healthcare, understanding the different types of suction catheter assembly machines has become essential for manufacturers, healthcare providers, and patients alike.

The Importance of Suction Catheters

Suction catheters are integral to modern medical procedures, particularly in respiratory care. These devices are used to clear mucus and secretions from a patient's airways, thereby preventing infections and facilitating easier breathing. Given their critical role, it is vital that suction catheters are manufactured with high precision and quality. This is where the Types of Suction Catheter Assembly Machine come into play.

These machines ensure that each catheter is assembled correctly, ensuring both functionality and safety. As the demand for these devices increases, so does the need for advanced, automated solutions in their assembly. Let's explore the various types of suction catheter assembly machines and their specific roles in the production process.

Automated Suction Catheter Assembly Machines

The most common and widely used type of suction catheter assembly machine is the automated system. These machines are designed to handle multiple stages of the assembly process, from the insertion of the catheter tube to the attachment of other components such as the valve and suction tip. Automation is key in these systems, reducing human error, increasing production speed, and maintaining consistency across batches.

Automated Types of Suction Catheter Assembly Machine offer several advantages. They are capable of high-speed production, ensuring that large volumes of catheters can be produced in a relatively short period. Additionally, they are often equipped with sensors that monitor the assembly process in real-time, flagging any issues before the product reaches the end of the line. This built-in quality control is crucial in maintaining high standards in the medical device industry.

Semi-Automatic Suction Catheter Assembly Machines

For manufacturers looking to balance cost-effectiveness and precision, semi-automatic suction catheter assembly machines provide an ideal solution. These machines typically require some level of manual intervention, but they still incorporate automated features to assist in the assembly process. For instance, an operator may load the components into the machine, but the machine itself will handle the bulk of the work, such as positioning and attaching the suction catheter parts.

The semi-automatic Types of Suction Catheter Assembly Machine offer flexibility, making them suitable for smaller production runs or companies that are transitioning to larger-scale manufacturing. They can also be customized to meet specific production requirements, which is a significant benefit for manufacturers dealing with specialized catheter designs.

Manual Suction Catheter Assembly Machines

Although automation has made significant inroads in the medical device manufacturing sector, manual assembly machines are still in use, particularly for niche or low-volume productions. Manual Types of Suction Catheter Assembly Machine typically involve a high degree of human involvement, where operators assemble each component by hand, often using jigs and fixtures to aid the process.

While manual systems are slower and more labor-intensive compared to automated solutions, they offer precision for specialized or customized catheter designs that may not be easily handled by fully automated machines. This type of assembly machine is often found in smaller manufacturing facilities or businesses that focus on creating bespoke suction catheters.

Benefits of the Various Types of Suction Catheter Assembly Machines

Each type of Suction Catheter Assembly Machine brings unique benefits to the manufacturing process. Automated machines offer high throughput, reduced labor costs, and increased consistency in quality. Semi-automatic machines strike a balance between cost and precision, allowing for flexibility in production. Manual machines, on the other hand, remain valuable in certain circumstances where high customization or low-volume production is required. Furthermore, advancements in technology are constantly improving the capabilities of these machines. Modern machines are now equipped with advanced features such as AI-powered defect detection, predictive maintenance, and real-time quality control systems, all of which help ensure that each suction catheter meets stringent medical standards.

In summary, the Types of Suction Catheter Assembly Machine play a crucial role in ensuring that high-quality, reliable suction catheters are produced for healthcare settings worldwide. From fully automated systems to manual solutions, each type of machine offers distinct advantages depending on production needs. As the demand for medical devices continues to grow, manufacturers will rely more on these machines to meet stringent requirements for safety, speed, and precision. Investing in the right type of assembly machine can ultimately enhance production efficiency, lower costs, and contribute to the overall quality of the healthcare industry.

English

English русский

русский Español

Español