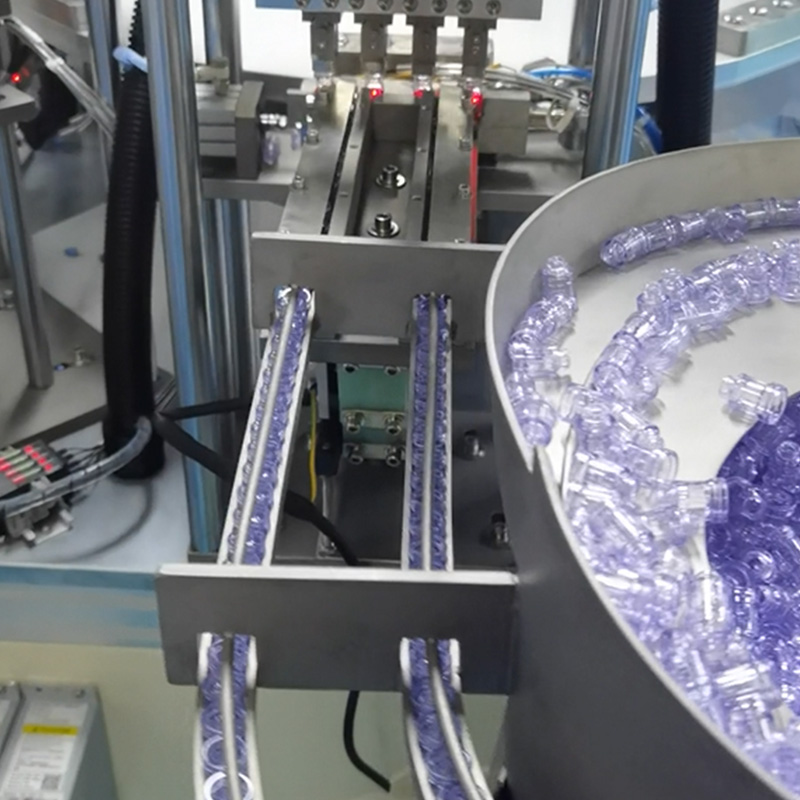

China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

In recent years, the medical manufacturing sector has witnessed a steady evolution in both precision and production efficiency, thanks to advancements in medical plastic mold machines. As hospitals and healthcare facilities demand increasingly specialized and reliable plastic components, manufacturers have turned to more refined and adaptable medical plastic mold machines to meet these needs. These devices are now central to the production of essential components, such as syringe bodies, catheter parts, surgical tools, and diagnostic equipment housings.

The medical plastic mold machine is a vital piece of equipment designed specifically for producing medical-grade plastic components under strict hygiene and dimensional accuracy standards. Unlike general-purpose mold equipment, medical plastic mold machines are built to comply with stringent regulatory requirements, such as ISO 13485, and are often housed in cleanroom environments. The high level of precision these machines offer ensures that every component meets the necessary safety and functional criteria demanded by the healthcare industry.

One of the key features of today’s medical plastic mold devices is their ability to maintain consistent performance while operating at high volumes. Modern medical plastic mold devices are equipped with automated monitoring systems, which track temperature, pressure, and cycle time in real time. This helps manufacturers minimize waste and reduce variability in production, thereby ensuring greater uniformity in each batch of medical components.

Beyond performance, the adaptability of the medical plastic mold machine is also contributing to its growing significance in the industry. These machines can be quickly retooled to produce a wide variety of components. For example, a single medical plastic mold machine can be used to manufacture both small, intricate parts for minimally invasive instruments and larger items such as containers or enclosures for diagnostic equipment. This flexibility allows manufacturers to respond to changing medical demands efficiently and cost-effectively.

Sustainability is also becoming a focus. Many manufacturers are now developing medical plastic mold devices that support the use of biocompatible and recyclable materials. These materials must still meet strict durability and hygiene standards, which makes the role of the medical plastic mold machine even more critical. The ability of the medical plastic mold device to precisely control molding parameters ensures that even eco-friendly materials can be formed into highly reliable medical products.

Companies specializing in medical plastic mold equipment are also investing heavily in research and development to enhance their systems’ capabilities. Advanced medical plastic mold devices now integrate with digital twin technologies, allowing engineers to simulate the entire molding process before actual production begins. This helps to identify potential issues in the mold design or process settings ahead of time, saving time and reducing costs associated with rework or quality defects.

In addition to technological advancements, there is a growing emphasis on training operators to work with medical plastic mold machines effectively. As the complexity of medical components increases, skilled technicians are essential for maintaining the performance and reliability of the medical plastic mold equipment. Manufacturers are establishing partnerships with technical institutes and training centers to ensure a pipeline of qualified professionals who understand the nuances of working with medical plastic mold devices.

Looking ahead, the demand for compact, portable, and customized medical plastic mold machines is likely to rise, particularly with the continued growth of point-of-care diagnostics and home healthcare technologies. As this trend continues, the industry will increasingly rely on modular and scalable medical plastic mold devices that can be easily integrated into decentralized production systems.

In summary, the role of the medical plastic mold machine in today’s healthcare landscape is more essential than ever. From producing high-precision components to enabling sustainable manufacturing practices, these machines and their associated medical plastic mold devices are setting new standards for quality and efficiency. With continuous innovation, investment, and skill development, the future of medical plastic molding is well-positioned to support the evolving needs of global healthcare.

English

English русский

русский Español

Español