China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

A Fully Automated Production Line for Suction Catheters has become a practical direction for medical device factories that want predictable quality and cleaner production workflows. Many buyers who visit our plant often share their concerns: frequent inspection pressure, rising labor hours, unstable manual handling of narrow tubing, and difficulty maintaining consistent results during long production runs. Our factory builds automation equipment engineered specifically for medical device manufacturing, so the line is designed around accuracy, traceability, and stable cycle time.

1. Precision in Every Step

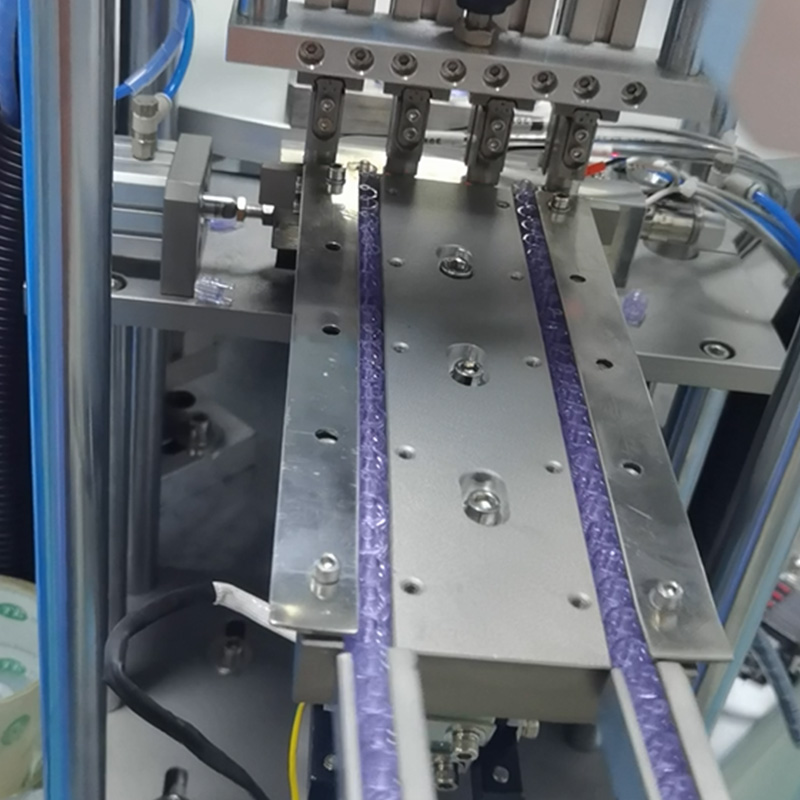

Catheter manufacturing requires stable movement and tight positioning control, especially during forming, cutting, and assembly. Manual or semi-manual setups often struggle when operators rotate, or when multiple shifts use slightly different handling methods. A Fully Automated Production Line for Suction Catheters changes this by relying on micron-level control systems that manage motion consistently.

Our equipment uses coordinated robotic mechanisms and programmable modules. This level of precision helps reduce deviations and supports steady output. Because suction catheters involve slender materials, even a small misalignment can cause interruptions. Automated positioning helps maintain a smoother workflow and reduces the number of small issues that normally slow teams down.

2. Flexible Structure for Different Designs

Factories seldom make only one model of catheter. Length, material hardness, connector shapes, and packaging styles often vary between clients. This creates stress for production teams who want automation but worry that rigid machines may not match future products.

The equipment's modular design supports adjustments without upsetting the entire workflow. This works well for a Fully Automated Production Line for Suction Catheters, as it can integrate steps such as precise cutting, controlled welding, liquid dispensing, or visual checks based on the product drawing. Because the system can handle metals, plastics, and other common materials, it can keep up with new variations without forcing a complete rebuild. This flexibility helps factories plan long-term capacity without guessing future specifications.

3. Higher Efficiency Without Heavy Labor

Many plants still rely on workers to handle repetitive catheter tasks such as feeding, trimming, or inspecting. These steps consume time and create bottlenecks. Our automation equipment is engineered to run continuously through robotic arms, conveyors, and coordinated stations. Real-time monitoring helps operators see performance changes early and adjust parameters before small issues grow.

A Fully Automated Production Line for Suction Catheters helps reduce manual handling and supports smooth transitions between steps. By keeping the process flowing, the line supports consistent cycle time, stable throughput, and less fatigue for the team. Production managers often note that this reduces the stress of balancing staff availability with order schedules.

4. Quality Control That Works During Production

Catheters require steady dimensional accuracy and surface quality. Late-stage findings force rework and slow down shipping timelines. Our automation equipment integrates visual inspection systems and control algorithms directly into the production process. Instead of only checking finished goods, the line detects deviations at the moment they appear.

A Fully Automated Production Line for Suction Catheters offers a structured and predictable manufacturing approach for factories moving toward higher output and cleaner process control. With precise engineering, modular layouts, continuous operation, and integrated inspection, the equipment supports stable catheter production without complicating daily work. If you need alternative angles for the titles or want a version written in a more promotional tone, I can prepare another draft anytime.

English

English русский

русский Español

Español