China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

A Fully Automated Production Line for Syringes is becoming a practical direction for many medical device factories that want stable output, predictable quality, and less dependence on manual inspection. Buyers who visit our plant often share similar concerns: inconsistent assembly results, rising labor costs, slow quality checks, and difficulty keeping up with project timelines when orders grow. With automation getting more accessible, many teams want a line that simply works—steady, clean, and accurate.

Our factory focuses on equipment such as the Safety Self-Destructive Syringe Automatic Assembly Machine, which fits naturally into a modern automated line. Below is a clear look at how this type of machinery answers real production problems and what makes it suitable for syringe manufacturers who want a stable upgrade.

1. Assembly Stability and Component Quality

A key worry for many medical manufacturers is the consistency of mechanical movement and alignment. Manual assembly can fluctuate from shift to shift, while semi-automatic setups still rely on operator judgment. A Fully Automated Production Line for Syringes addresses this by using components built for tight tolerances.

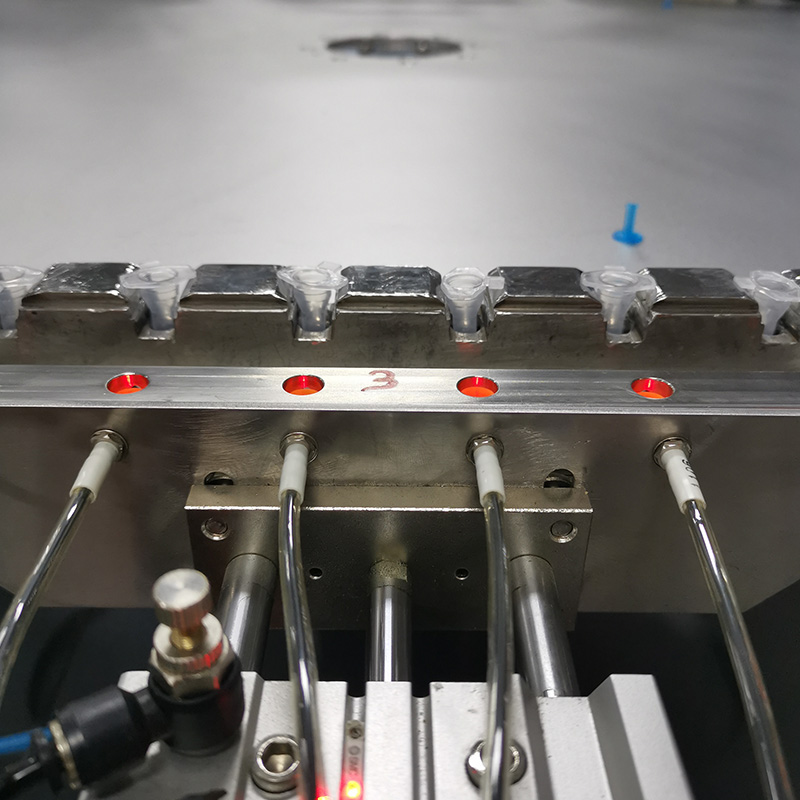

In our machine, electrical and pneumatic parts come from established suppliers abroad. Mechanical structures are CNC-machined with defined hole positions, supporting accurate assembly of every syringe. Parts that contact the product—mainly stainless steel and aluminum alloy—go through hard anodizing and electroless nickel plating. These treatments keep surfaces clean, durable, and production-friendly. This reduces unexpected downtime caused by part wear or surface contamination.

2. Customization that Fits Real-World Processes

Many factories worry that automation requires them to change their existing process flow. In practice, the equipment can be engineered according to customer drawings and actual samples. This means the line adapts to your syringe design, instead of forcing you to adjust your design for the line.

A Fully Automated Production Line for Syringes also supports process-specific functions. For example, after the syringe is assembled, our machine performs reverse force detection and online pressure checks. These two checks help confirm that key functional points remain within acceptable ranges. Instead of finding issues at the packing stage, problems are noticed immediately during assembly. This removes a major bottleneck for quality teams who often struggle with late-stage rejects.

3. Visual Detection for Key Components

A common weak spot in syringe assembly is the placement of O-rings and threaded needle holders. These parts are small but critical. Even a slight misalignment can slow down production or cause customer complaints.

To address this, the equipment integrates CCD visual inspection. The system checks alignment, presence, and positioning in real time. This feature helps the Fully Automated Production Line for Syringes maintain steady quality without increasing operator workload. Instead of relying on manual sampling, visual detection works continuously and flags issues early.

4. Sorting and Productivity

Factories often struggle with inspection manpower, especially when daily output rises. Our machine includes automatic product sorting, sending qualified and unqualified pieces into different bins. This clears a major step that normally requires several workers.

Production capacity ranges from 3,500–5,000 sets per hour, fitting mass-production needs without adding floor pressure. The machine operates with standard compressed air (0.45–0.65 MPa) and consumes 1.8–2.0 kW of power, which is manageable for many workshops. Its footprint of about 2.5 m × 2.5 m × 1.7 m fits easily into typical plant layouts.

A Fully Automated Production Line for Syringes helps manufacturers move from labor-dependent assembly to a steady, predictable workflow. With precise components, visual inspection, customizable processes, and automatic sorting, the equipment provides a clear path to cleaner production and more confidence during customer audits.

English

English русский

русский Español

Español