China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The medical device industry has witnessed a significant transformation in recent years, driven by a growing need for automation and precision in manufacturing processes. Among the emerging technologies, the Plasma Blood Port Stopper Clamp Assembly Machine plays a vital role in enhancing the production of blood port stoppers, a critical component used widely in various medical applications.

Growing Market Demand for Blood Port Stoppers

Blood port stoppers are essential devices used to securely close blood ports during procedures such as dialysis, blood transfusions, and intravenous treatments. With the increasing prevalence of chronic diseases requiring long-term vascular access, the demand for high-quality blood port stoppers continues to rise steadily. The Plasma Blood Port Stopper Clamp Assembly Machine addresses this growing demand by providing an automated solution that significantly improves production capacity and consistency.

As healthcare providers seek safer and more reliable devices, manufacturers face pressure to enhance the quality of blood port stoppers while maintaining cost-effectiveness. The Plasma Blood Port Stopper Clamp Assembly Machine offers a means to achieve this balance through precise assembly processes that minimize human error and ensure uniformity in each product.

Target Customers: Medical Device Manufacturers and Laboratory Equipment Suppliers

The primary users of the Plasma Blood Port Stopper Clamp Assembly Machine are medical device manufacturers specializing in vascular access products and laboratory equipment suppliers. These companies benefit from integrating the machine into their production lines, as it automates complex assembly tasks that were traditionally manual and labor-intensive.

By adopting the Plasma Blood Port Stopper Clamp Assembly Machine, manufacturers can enhance their operational efficiency, reduce production times, and maintain higher quality standards. This equipment is particularly valuable for enterprises looking to scale production while complying with stringent regulatory requirements in the medical industry.

Application Scenarios in Healthcare Manufacturing

The Plasma Blood Port Stopper Clamp Assembly Machine finds its application in various medical manufacturing settings, notably in blood dialysis equipment production. Dialysis centers rely heavily on durable and reliable blood port stoppers to ensure patient safety and treatment efficacy. The machine facilitates the efficient production of these components by streamlining the assembly process, ensuring each stopper is securely and accurately assembled.

Beyond dialysis equipment, the Plasma Blood Port Stopper Clamp Assembly Machine is also utilized in the manufacturing of blood transfusion devices and intravenous therapy accessories. In all these applications, the machine’s capability to maintain assembly precision reduces the risk of leakage or contamination, thereby supporting better patient outcomes.

Enhancing Production Quality and Efficiency

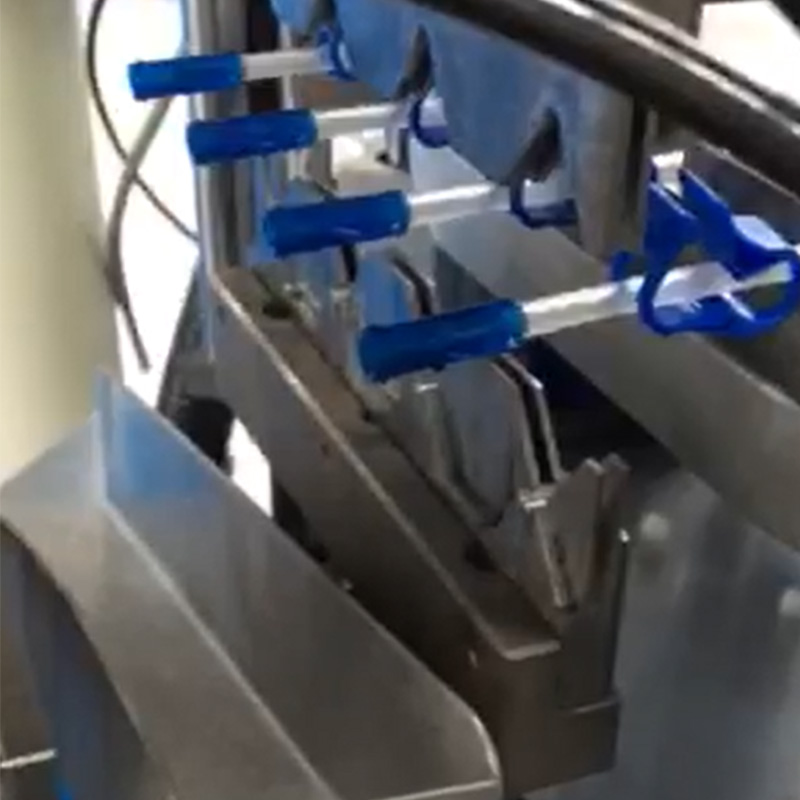

One of the key advantages of the Plasma Blood Port Stopper Clamp Assembly Machine is its ability to maintain consistent quality throughout the manufacturing process. The machine employs advanced mechanisms to ensure each blood port stopper meets exact specifications, minimizing variations that could compromise device performance.

Additionally, the automation provided by the Plasma Blood Port Stopper Clamp Assembly Machine significantly reduces reliance on manual labor, which can be subject to fatigue and inconsistency. This is to improve production rates, cost savings, and the ability to meet increasing market demand without sacrificing quality.

Industry Outlook and Future Prospects

The medical manufacturing industry is expected to continue its trend toward increased automation and precision engineering. The Plasma Blood Port Stopper Clamp Assembly Machine stands out as a key enabler for manufacturers aiming to innovate and stay competitive.

As the demand for vascular access devices grows, especially in regions with expanding healthcare infrastructure, the Plasma Blood Port Stopper Clamp Assembly Machine will play a crucial role in meeting the needs of healthcare providers and patients alike.

In conclusion, the Plasma Blood Port Stopper Clamp Assembly Machine is more than just an assembly tool; it represents a strategic investment in improving healthcare device manufacturing. By combining efficiency, precision, and scalability, it supports the medical industry’s goal of delivering safe and reliable blood port stoppers, ultimately contributing to better patient care.

English

English русский

русский Español

Español