China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The medical device industry thrives on precision, sterility, and reliability. At the heart of ensuring these qualities for countless products – from surgical kits to diagnostic devices – lies the critical component of sterile barrier packaging. Enter the transformative technology of the Medical Breathable Cover Welding Film Assembly Equipment Machine, a sophisticated solution rapidly becoming indispensable for manufacturers prioritizing efficiency, quality, and compliance in sterile packaging production.

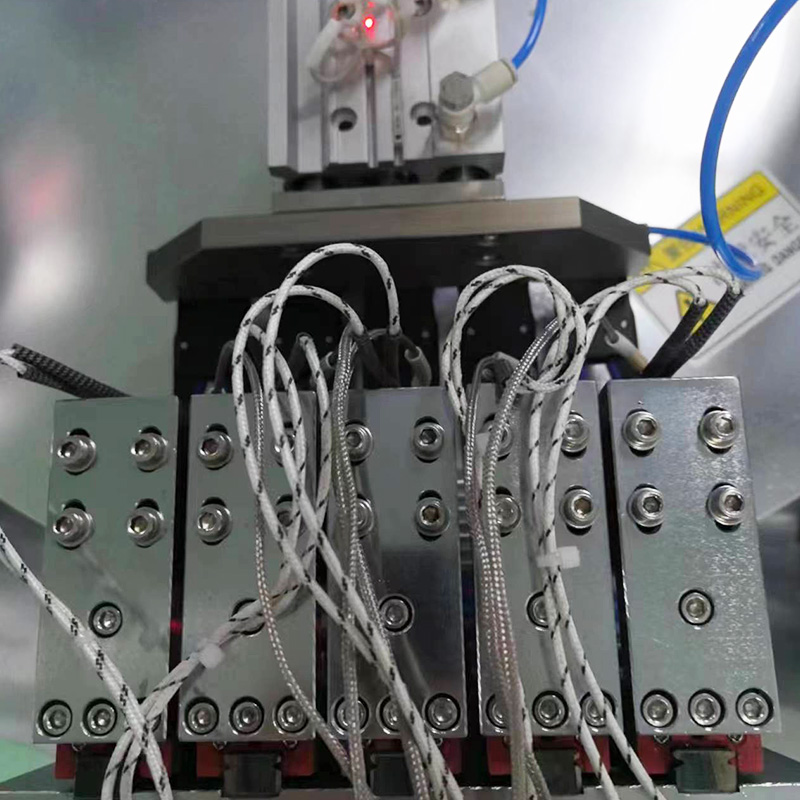

Gone are the days of relying solely on manual assembly or less specialized machinery for creating these vital protective components. The modern Medical Breathable Cover Welding Film Assembly Equipment Machine represents a leap forward in automation and precision engineering. Designed specifically for handling the delicate yet robust films required for breathable medical covers, this equipment integrates multiple processes into a seamless, controlled operation. Its core function is the precise welding of specialized breathable film layers, often combined with non-woven materials or other substrates, to form the final sterile barrier assembly.

The significance of the Medical Breathable Cover Welding Film Assembly Equipment Machine cannot be overstated. Consistent, high-integrity seals are paramount. Any weak weld or imperfection compromises sterility, potentially to product recalls and patient risk. This advanced machinery utilizes controlled heat, pressure, and dwell time parameters, often monitored by sophisticated sensors and programmable logic controllers (PLCs), to ensure every weld meets stringent specifications. The precision inherent in a well-calibrated Medical Breathable Cover Welding Film Assembly Equipment Machine directly translates to enhanced product safety and reduced waste.

Furthermore, efficiency is a major driver for adoption. A high-performance Medical Breathable Cover Welding Film Assembly Equipment Machine significantly accelerates production compared to manual methods. Automated feeding systems precisely position the breathable film layers, while the welding and cutting mechanisms operate at optimized speeds. This increased throughput allows manufacturers to meet growing market demands without compromising on quality or necessitating excessive labor costs. The operational consistency provided by the Medical Breathable Cover Welding Film Assembly Equipment Machine also minimizes variability, to more predictable yields and streamlined operations.

The versatility of modern Medical Breathable Cover Welding Film Assembly Equipment Machine models is another key advantage. They can be configured to handle various film types (Tyvek®, medical-grade paper, specialized laminates) and accommodate different cover sizes and shapes. This flexibility is crucial for contract packagers and device manufacturers producing a diverse range of products. Whether creating simple pouches or complex multi-panel sterile barrier systems, the Medical Breathable Cover Welding Film Assembly Equipment Machine can be adapted to the task, offering significant return on investment through reduced changeover times and broader application scope.

Compliance with international standards (ISO 11607, ASTM F88) for medical packaging is non-negotiable. Reputable manufacturers of the Medical Breathable Cover Welding Film Assembly Equipment Machine design their systems with these regulations in mind. Features often include comprehensive data logging capabilities, traceability functions, and validation protocols to ensure the machine's output consistently meets the required quality levels. Utilizing a validated Medical Breathable Cover Welding Film Assembly Equipment Machine simplifies the often-complex process of regulatory documentation and audits for medical device producers.

Looking ahead, integration with Industry 4.0 principles is becoming increasingly common. Advanced Medical Breathable Cover Welding Film Assembly Equipment Machine units offer connectivity for real-time monitoring of production metrics, predictive maintenance alerts, and remote diagnostics. This connectivity enhances overall equipment effectiveness (OEE) and provides valuable data for continuous process improvement initiatives within the manufacturing environment. The evolution of the Medical Breathable Cover Welding Film Assembly Equipment Machine continues to focus on smarter, more connected, and even more user-friendly operation.

In conclusion, the Medical Breathable Cover Welding Film Assembly Equipment Machine is far more than just a production tool; it is a cornerstone technology for modern medical device packaging. By delivering unmatched precision in welding breathable films, boosting production efficiency, ensuring regulatory compliance, and offering adaptable configurations, this specialized equipment directly addresses the critical needs of sterile barrier manufacturers. As the demand for safe, reliable, and innovative medical packaging grows, the role of the sophisticated Medical Breathable Cover Welding Film Assembly Equipment Machine will only become more central to the industry's success and its unwavering commitment to patient safety. Investing in this technology represents a strategic move towards robust, high-quality, and compliant sterile packaging manufacturing.

English

English русский

русский Español

Español