China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The relentless demand for sterile, high-reliability respiratory and suction consumables in intensive care units worldwide has accelerated innovation in specialized medical assembly technology. Three distinct equipment categories—closed suction assembly machines, suction catheter assembly machines, and oral suction tubing assembly machines—are transforming production paradigms while addressing core clinical priorities.

Redefining Catheter Manufacturing Standards

Unlike traditional catheter production systems, the modern closed suction assembly machine integrates multiple critical functions within sterile environments. " "What distinguishes these systems is their ability to hermetically seal catheter components within protective sleeves during final assembly," explains Dr. Elena Rodriguez, biomedical engineer at MedTech Dynamics. ""Traditional lines assemble components before secondary packaging, creating contamination risk windows."" This integrated approach allows the closed suction assembly machine to maintain ISO Class 7 conditions throughout valve attachment, sleeve welding, and final sealing processes. The latest generation of closed suction assembly machine models now incorporates in-line particulate monitoring and valve function testing—capabilities absent in conventional catheter production.

Infection Control Through Automated Precision

ICU infection prevention protocols heavily depend on flawless consumable performance. Here, specialized suction catheter assembly machines deliver consistency. ""Manual assembly variations in catheter tip geometry or connector seating were historically significant contamination vectors," states ICU Director Marcus Thorne of Boston Metro Hospital. ""Automated suction catheter assembly machines eliminate this variability through micron-precise robotic placement and laser verification systems."" Advanced suction catheter assembly machines now feature real-time biofilm detection optics and automated rejection of units with microscopic surface imperfections. This technological rigor explains why hospitals specify ICU consumables exclusively from facilities utilizing validated suction catheter assembly machines.

Scalable Flexibility Across Patient Demographics

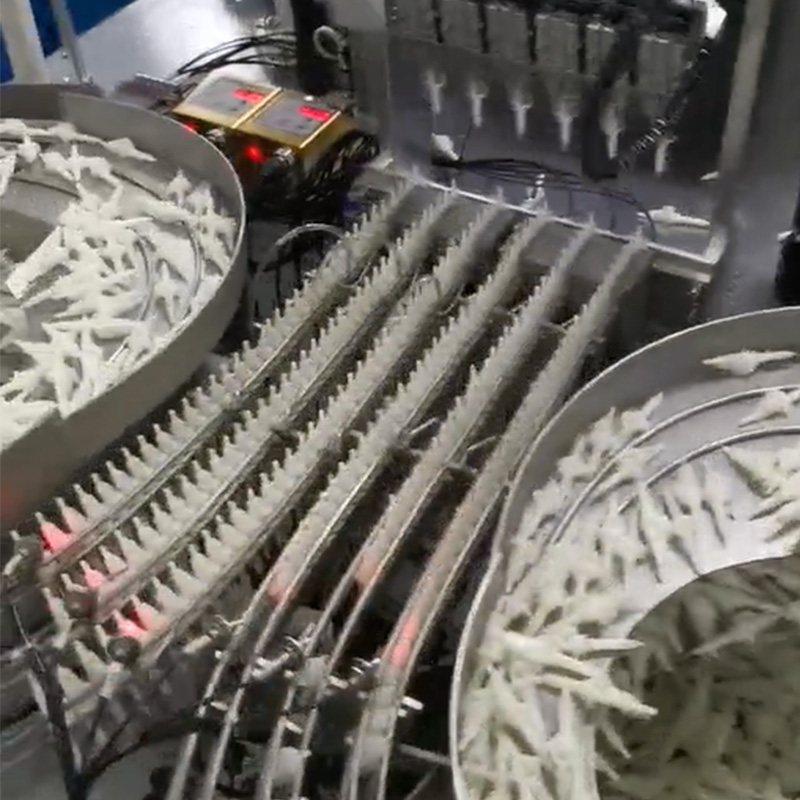

Addressing diverse anatomical requirements, modern oral suction tubing assembly machines demonstrate remarkable adaptability. " "The question isn't whether they handle neonatal and adult variants," clarifies production VP Sarah Chen at VitalCare Manufacturing. ""It's how rapidly they switch between product families." "Contemporary oral suction tubing assembly machines accomplish changeovers in under 15 minutes through automated tooling calibration and recipe-driven parameter adjustments. This flexibility extends to material compatibility; premium oral suction tubing assembly machines process everything from ultra-soft neonatal-grade silicones to reinforced adult PVC formulations without compromising seal integrity at Y-junctions. The latest oral suction tubing assembly machines further incorporate dual-track configurations, allowing simultaneous production of different product lines.

Converging Technological Advancements

These specialized platforms increasingly share core technologies:

Vision-guided robotics in suction catheters assembly machines now inform development of more sophisticated optical alignment in closed suction assembly machine platforms

Cleanroom integration standards pioneered for closed suction assembly machines have become baseline requirements for new oral suction tubing assembly machines

Data traceability architectures developed for suction catheters assembly machines now enable comprehensive device histories from all three system types

Industry Impact and Future Outlook

Regulatory bodies are taking note of these advancements. The FDA's 2024 guidance on "Continuous Manufacturing of Critical Care Consumables" explicitly references validation protocols for closed suction assembly machines and suction catheter assembly machines. Meanwhile, emerging markets demonstrate particular interest in modular oral suction tubing assembly machines capable of serving diverse patient populations with minimal footprint. As respiratory care complexity increases, the synergy between these specialized assembly platforms—the contamination-proof closed suction assembly machine, the micron-precise suction catheter assembly machines, and the adaptable oral suction tubing assembly machines—will remain fundamental to delivering life-sustaining devices that meet the exacting demands of modern critical care medicine.

English

English русский

русский Español

Español