China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The relentless pursuit of enhanced patient safety and streamlined medical manufacturing has taken a significant step forward with the increasing adoption of the One Link Needle-Free IV Connector Assembly Machine. This specialized equipment is transforming how crucial intravenous (IV) connector components are produced, directly addressing critical needs within modern healthcare settings.

IV therapy is fundamental in hospitals and clinics worldwide, delivering medications, fluids, and nutrients directly into a patient's bloodstream. Traditional needle-based systems, while effective, carry inherent risks, including needlestick injuries for healthcare workers and potential pathways for bloodstream infections (BSIs). Needle-free IV connectors were developed as a vital safety innovation, minimizing these risks by allowing medication administration and line access without needles. The reliability and sterility of these connectors are paramount.

This is where the One Link Needle Free IV Connector Assembly Machine demonstrates its indispensable value. Manufacturing needle-free connectors requires exceptional precision, consistency, and adherence to the strictest sterility standards. Manual or less sophisticated automated assembly processes can be susceptible to variations, potential contamination events, and slower production rates. The One Link Needle Free IV Connector Assembly Machine is engineered specifically to overcome these challenges.

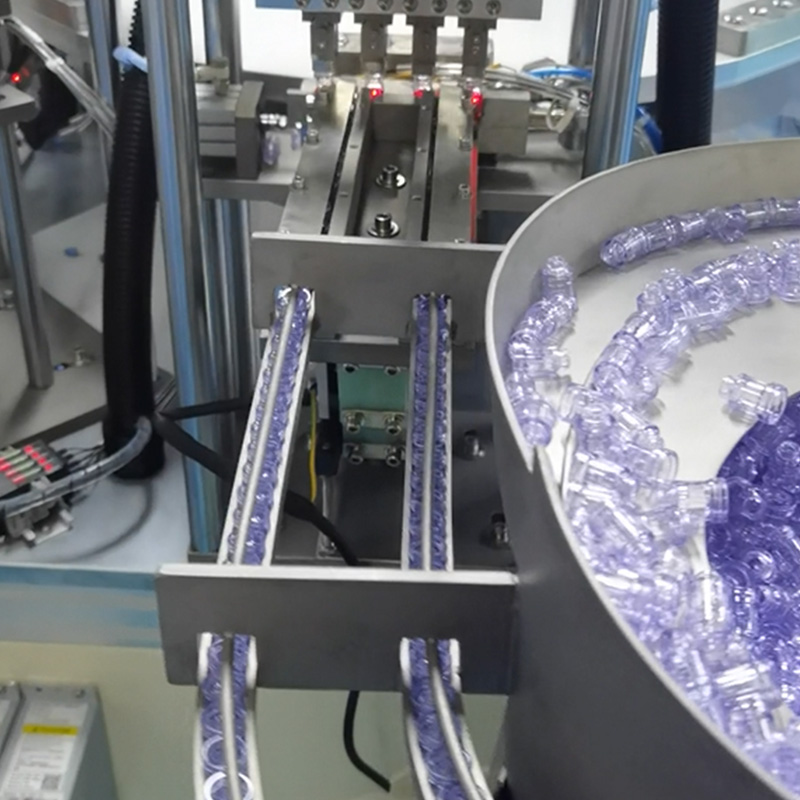

The core function of the One Link Needle Free IV Connector Assembly Machine is the automated, high-precision assembly of the complex internal mechanisms of needle-free IV connectors. It meticulously handles and assembles tiny, critical components—such as sealing septums, housing parts, and internal valves—with micron-level accuracy. This level of precision, consistently delivered by the One Link Needle Free IV Connector Assembly Machine, is essential for ensuring the connector functions correctly every time: maintaining a secure, leak-proof seal when closed and providing a safe, reliable access point when accessed with a needleless syringe or administration set.

Consistency and reliability in manufacturing are non-negotiable in the medical device industry. The One Link Needle Free IV Connector Assembly Machine excels in delivering uniform output. By automating the assembly process, drastically reduces the potential for human error inherent in manual assembly lines. Every connector produced by the One Link Needle Free IV Connector Assembly Machine meets identical specifications, contributing directly to predictable performance in clinical use. This consistency is a cornerstone of quality assurance for manufacturers utilizing the One Link Needle Free IV Connector Assembly Machine.

Furthermore, efficiency is a major benefit. The One Link Needle Free IV Connector Assembly Machine operates at significantly higher speeds than manual assembly, enabling manufacturers to scale production to meet the growing global demand for these safety-critical devices. This scalability, facilitated by the One Link Needle Free IV Connector Assembly Machine, ensures a reliable supply chain for healthcare providers.

The impact of devices assembled on the One Link Needle Free IV Connector Assembly Machine extends directly to the bedside. Needle-free connectors are recognized as a key component in reducing needlestick injuries among nurses and other clinical staff, enhancing workplace safety. More importantly, properly functioning connectors are crucial in preventing catheter-related bloodstream infections (CRBSIs), a serious and costly healthcare-associated complication. The precision assembly guaranteed by the One Link Needle-Free IV Connector Assembly Machine helps ensure the integrity of the connector's seal, a critical barrier against pathogens.

Manufacturers investing in the One Link Needle Free IV Connector Assembly Machine report tangible benefits." "Integrating the One Link Needle Free IV Connector Assembly Machine into our production line was transformative," stated a Production Manager at a medical device company. ""The consistency and throughput improvements were immediate, and the reduction in assembly-related defects has significantly bolstered our quality metrics for these vital components. The One Link Needle Free IV Connector Assembly Machine provides the level of control we need.""

As healthcare systems globally continue to prioritize infection prevention and healthcare worker safety, the demand for high-quality needle-free IV connectors remains robust. The One Link Needle Free IV Connector Assembly Machine represents a sophisticated manufacturing solution directly supporting these goals. Its ability to deliver precision, consistency, sterility assurance, and efficiency makes the One Link Needle Free IV Connector Assembly Machine a valuable asset for medical device producers committed to advancing patient care and safety through manufacturing technology. The ongoing deployment of the One Link Needle Free IV Connector Assembly Machine signifies a positive trend towards more reliable and safer intravenous therapy management. The contribution of the One Link Needle Free IV Connector Assembly Machine to modern medical device manufacturing is both clear and significant

English

English русский

русский Español

Español