China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The global healthcare landscape continues its relentless demand for high-quality, disposable medical products—from syringes and IV sets to diagnostic cartridges and surgical kits. Behind this critical supply chain, a transformative force is gaining momentum: the advanced medical plastic consumable assembly machine. These sophisticated systems are rapidly becoming the backbone of modern medtech production, ensuring safety, precision, and scalability like never before.

Market Drivers Fueling Automation

Several converging factors propel the adoption of specialized plastic consumable medical assembly machine solutions. The lingering impact of global health challenges underscores the vital need for resilient, high-volume production of essential disposables. Simultaneously, stringent regulatory requirements (FDA, MDR, ISO 13485) demand impeccable traceability and near-zero defect rates, achievable consistently only through advanced automation. Furthermore, labor shortages and rising costs in traditional manufacturing hubs make the efficiency gains offered by a robust medical consumable assembly machine increasingly compelling. According to a recent Global MedTech Insights report, investments in such automation for consumables are projected to grow by 12.3% CAGR over the next five years.

Engineering Precision for Critical Applications

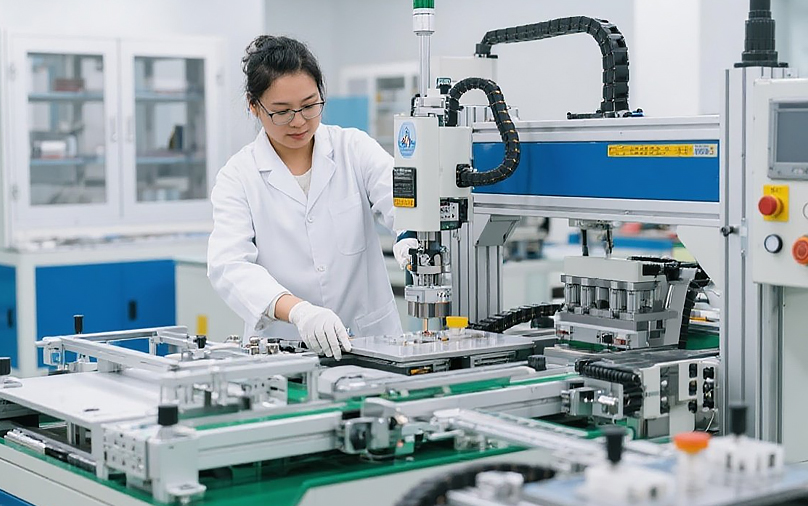

Modern medical plastic consumable assembly machine designs are marvels of engineering tailored for the medtech sector’s unique demands. They operate within controlled environments (often ISO Class 7 or 8 cleanrooms), incorporate precision vision systems for microscopic defect detection, and handle delicate components like thin-film membranes or microfluidic channels with sub-micron accuracy. The core strength of a well-designed plastic consumable medical assembly machine lies in its flexibility—quick changeovers between different consumable product lines are essential in today's diverse market. Integrated process monitoring and data logging are non-negotiable features, providing the comprehensive audit trails regulators require. Whether assembling complex respiratory masks or simple sample collection tubes, the reliability of the medical consumable assembly machine directly impacts patient safety.

Tangible Impact Across the Supply Chain

The strategic deployment of medical plastic consumable assembly machine technology delivers concrete benefits far beyond the factory floor. Manufacturers report significant reductions in product rejects (often exceeding 30%) compared to semi-automated lines, directly translating to cost savings and less waste. Enhanced consistency from these machines minimizes risks associated with human error, such as particulate contamination or improper sealing, critical factors for patient well-being. Moreover, the high throughput capabilities of a modern plastic consumable medical assembly machine enable manufacturers to scale production rapidly to meet surges in demand, enhancing supply chain resilience. This automation also facilitates cost-effective localized or regional manufacturing, bringing essential medical consumable assembly machine production closer to end markets and reducing logistical burdens.

The evolution of the medical plastic consumable assembly machine is far from static. The next generation is poised to embrace deeper integration of artificial intelligence and machine learning. AI algorithms will move beyond simple defect detection to predictive quality control, analyzing subtle process variations in real-time to prevent defects before they occur. Adaptive plastic consumable medical assembly machine systems will self-optimize parameters for different material batches or environmental conditions. Sustainability is also rising on the agenda; future medical consumable assembly machine platforms will need enhanced compatibility with bio-based or recycled plastics without compromising sterility or performance. Seamless integration into broader "smart factory" ecosystems, exchanging vital data with upstream molding operations and downstream packaging lines, will further elevate efficiency and visibility. The inherent flexibility built into the core design philosophy of the modern medical plastic consumable assembly machine ensures it remains a future-proof investment.

From ensuring the availability of billions of syringes during a pandemic to enabling the precise assembly of complex point-of-care diagnostic devices, the medical plastic consumable assembly machine has evolved into an indispensable component of global health infrastructure. Its role transcends mere automation; it is a guarantor of quality, safety, and accessibility for vital medical consumables. As technology advances, the sophistication, intelligence, and adaptability of the plastic consumable medical assembly machine will only increase. Manufacturers prioritizing strategic investment in these sophisticated medical consumable assembly machine solutions are not merely optimizing their operations; they are actively fortifying the very foundation of reliable healthcare delivery worldwide, one precisely assembled component at a time. The silent hum of these machines resonates with the promise of safer, more accessible care for all.

English

English русский

русский Español

Español