China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The global medical manufacturing landscape is undergoing a steady transformation as precision, hygiene, and efficiency become increasingly critical in product development. Among the core technologies reshaping this sector are plastic injection molding medical devices, medical device plastic molding assembly machines, and medical device molding assembly machine systems. These solutions are providing manufacturers with the tools necessary to meet both growing patient demand and stricter regulatory requirements.

The process of producing plastic injection molding medical devices has become a foundational method for creating complex, high-volume, and sterile components. Whether it's IV connectors, surgical tools, or implantable parts, the use of plastic injection molding medical devices allows for precise replication of intricate designs with minimal deviation. As healthcare providers continue to request lighter, safer, and more durable devices, this method is often the efficient and scalable choice.

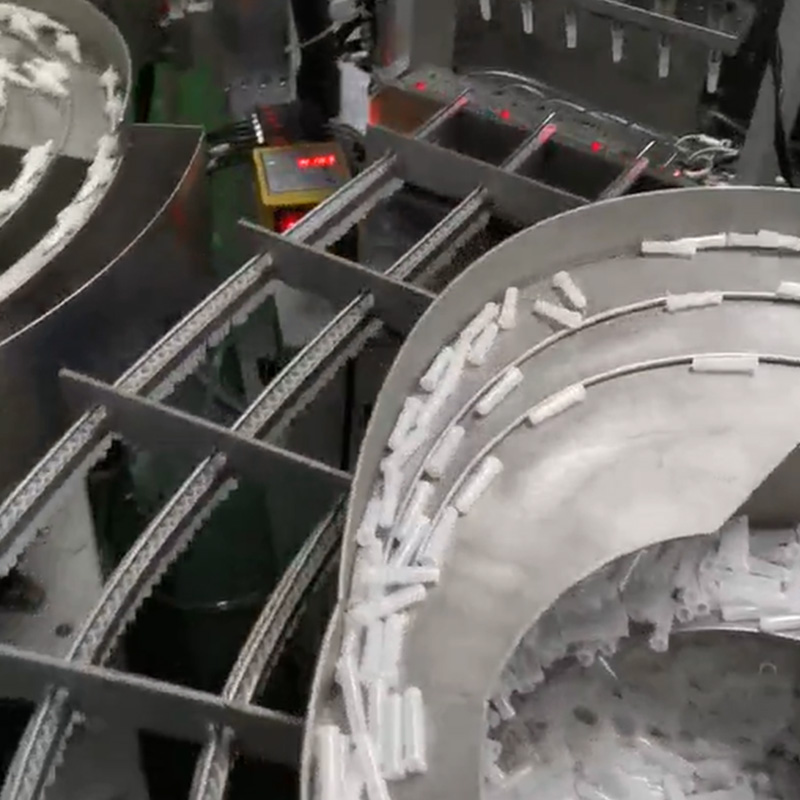

What strengthens the utility of plastic injection molding medical devices is the downstream automation provided by assembly machinery. The medical device plastic molding assembly machine plays a pivotal role in ensuring that molded components are assembled in a clean, consistent, and controlled environment. These machines reduce the possibility of human error, improve production repeatability, and significantly boost throughput. For manufacturers working with small and delicate parts, the medical device plastic molding assembly machine provides a critical advantage by handling the assembly with micron-level accuracy.

Likewise, the medical device molding assembly machine enables seamless integration of different molded parts into complete medical devices. This technology ensures that parts molded through the plastic injection molding medical devices process are efficiently transferred, aligned, and fastened into final assemblies. Many of today’s medical device molding assembly machine systems also include real-time inspection and quality control mechanisms, which further improve output reliability.

The growth of demand for plastic injection molding medical devices is also driven by the increasing adoption of single-use medical products. These products, including syringes, diagnostic cartridges, and catheter connectors, are often produced using plastic injection molding medical devices techniques due to their cost-effectiveness and design flexibility. Manufacturers are leveraging the benefits of the medical device plastic molding assembly machine to maintain a high standard of cleanliness, which is essential for sterile products.

In this environment, the medical device molding assembly machine serves as a bridge between raw material processing and final product packaging. Modern assembly systems offer modularity, allowing for quick transitions between different product types without major retooling. This adaptability is particularly important as product lifecycles shorten and customization becomes more common.

Furthermore, digitalization is enhancing the performance of both the medical device plastic molding assembly machine and the medical device molding assembly machine. Many systems now feature IoT connectivity, predictive maintenance, and integration with MES software, giving operators complete visibility into the performance of their plastic injection molding medical devices production lines.

Industry stakeholders recognize that as regulations evolve and product designs become more sophisticated, investment in automation will be key. The combination of plastic injection molding medical devices, coupled with efficient medical device plastic molding assembly machine solutions, positions manufacturers to meet quality expectations while remaining cost-competitive. Meanwhile, the medical device molding assembly machine provides the necessary scalability and traceability demanded in global supply chains.

In summary, the synergy between plastic injection molding medical devices, medical device plastic molding assembly machine, and medical device molding assembly machine technologies represents a major advancement in modern medical manufacturing. These tools collectively enable manufacturers to achieve greater consistency, lower production risk, and meet the rising expectations of healthcare markets across the world. As demand for innovative and reliable medical products continues to increase, these technologies are likely to play an even more vital role in the industry’s future.

English

English русский

русский Español

Español