China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The medical device industry continues to evolve with an increasing demand for precision, efficiency, and reliability. Among the many essential components used in modern medical care, the 3-way stopcock with extension tubing assembly machine has become a cornerstone in the production of infusion therapy systems. As hospitals and clinics expand their reliance on intravenous treatments and invasive monitoring, the tools that support these procedures—particularly three-way stopcocks—must be manufactured to exacting standards.

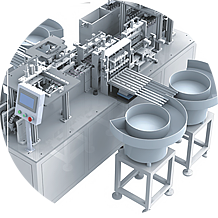

A 3-way stopcock with extension tubing assembly machine is designed to automate the production of critical fluid control components used in a variety of clinical applications. These machines assemble the valve body, rotating handle, male and female luer locks, and the extension tubing—all within a controlled, sterile manufacturing environment. With demand for these devices rising globally, manufacturers are upgrading to newer assembly systems that deliver higher output without compromising precision.

The importance of the 3-way stopcock in clinical medicine lies in its ability to regulate the flow of fluids or medications between multiple IV lines. In intensive care units, emergency departments, and surgical theaters, these devices allow for the connection of multiple infusion sources while giving healthcare providers full control over fluid administration. The growing use of 3 way stopcock components in assembly medicine has created a need for reliable production equipment that can meet strict regulatory and clinical performance requirements.

Modern medical three way valves assembly machines are engineered to meet this need. Equipped with vision-guided robotics, servo motors, and real-time inspection systems, these machines ensure that every valve assembled is functionally accurate and leak-proof. The process includes ultrasonic welding or solvent bonding of components, torque testing of the rotating handle, and automated placement of extension tubing. These features minimize human error and reduce the likelihood of component failure in the field.

One notable advantage of the new-generation 3 way stopcock with extension tubing assembly machine is its modularity. With interchangeable fixtures and programming flexibility, manufacturers can produce various configurations of stopcock devices, including models with different tubing lengths, connector types, and color-coded handles. This adaptability is particularly valuable in a global market where product specifications may vary by region or clinical protocol.

Beyond mechanical efficiency, these machines also contribute to quality control and traceability. Built-in sensors record assembly parameters such as force, speed, and alignment, creating a digital record for each unit produced. This data-driven approach allows for real-time quality assurance and supports compliance with regulatory frameworks like FDA 21 CFR Part 820 and ISO 13485. For medical device companies, this is essential to maintain consistency across high-volume production batches.

The role of 3 way stopcock devices in assembly medicine is expected to expand, especially as healthcare systems adopt more advanced infusion systems, central line access kits, and multi-lumen catheters. To support this shift, investment in automated medical three way valves assembly machines is becoming a priority for contract manufacturers and OEMs alike. These systems are being integrated into smart factories, where digital dashboards and predictive maintenance ensure uptime and reduced operational costs.

Workforce training is also evolving to support these complex machines. Operators are no longer limited to mechanical tasks but now engage with digital interfaces, interpret machine analytics, and conduct minor programming adjustments. As medical three way valves assembly machines become more sophisticated, they require a blend of mechanical and software literacy, prompting manufacturers to invest in cross-functional training programs.

In conclusion, the rise of the 3 way stopcock with extension tubing assembly machine marks a significant step forward in the precision manufacturing of medical components. These machines, together with the expanding use of 3 way stopcock devices in assembly medicine and the advancement of medical three way valves assembly machines, are helping to set new benchmarks for safety, performance, and scalability in medical device production. As healthcare technology progresses, so too will the machinery behind the scenes—quietly ensuring that every component performs exactly as intended.

English

English русский

русский Español

Español