China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The pharmaceutical industry is at the cusp of a technological revolution with the advent of the Automatic Syringe Equipment Filling Assembly Machine, a groundbreaking innovation that integrates high-precision liquid filling, capping, plugging, assembly, labeling, and packaging into one seamless system. This device is set to redefine the standards of accuracy and efficiency in the production of injectable medications.

The increasing demand for injectable drugs has led to a surge in the need for sophisticated machinery that can handle various viscosities of pharmaceutical liquids with precision. The Automatic Syringe Equipment Filling Assembly Machine has been designed to meet these challenges head-on, offering intelligent control systems that can adapt to a wide range of liquid viscosities, ensuring consistent and reliable syringe filling.

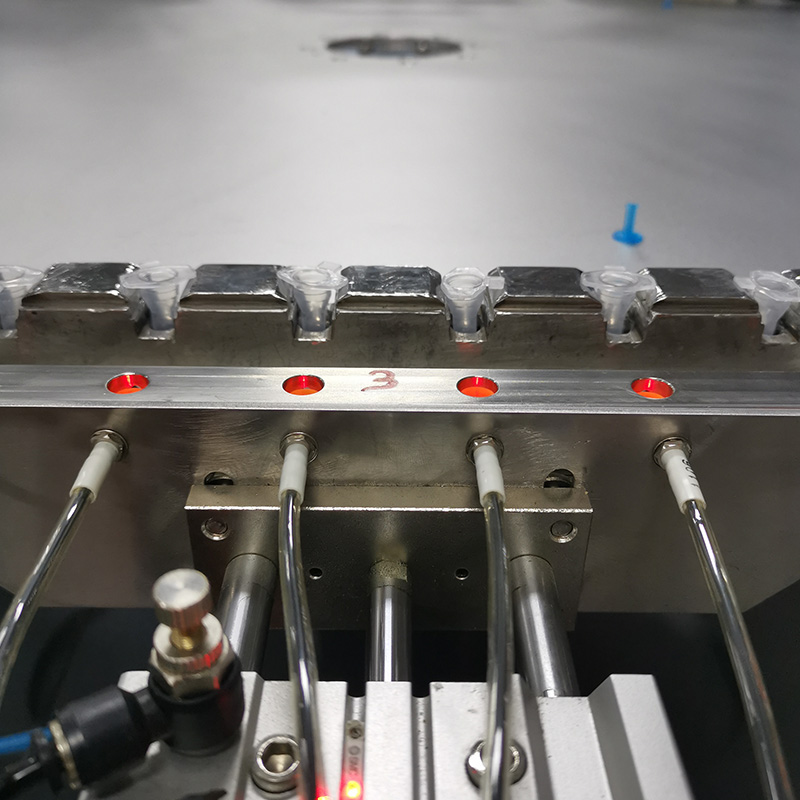

One of the standout features of the Automatic Syringe Equipment Filling Assembly Machine is its advanced vision recognition technology. This system enables the machine to accurately detect and adjust for the presence of air bubbles, ensuring that each syringe is filled to the precise volume required. This level of accuracy is crucial in the pharmaceutical industry, where even the smallest discrepancies can have significant consequences.

In addition to its filling capabilities, the Automatic Syringe Equipment Filling Assembly Machine also excels in the capping process. The machine's integrated capping mechanism ensures that each syringe is securely sealed, protecting the medication from contamination and preserving its efficacy. This feature is particularly important given the stringent quality control standards that pharmaceutical products must meet.

The plugging phase of syringe production is also streamlined with the Automatic Syringe Equipment Filling Assembly Machine. The machine's automated plugging system ensures that the needle guard is securely attached to each syringe, providing an additional layer of safety for both patients and healthcare providers.

The assembly of syringes is further enhanced by the machine's ability to handle a variety of syringe types and sizes. This flexibility allows pharmaceutical manufacturers to produce a wide range of products using a single piece of equipment, reducing costs and increasing production efficiency.

Labeling is another area where the Automatic Syringe Equipment Filling Assembly Machine excels. Its integrated labeling system ensures that each syringe is clearly marked with all necessary information, including dosage, expiration dates, and other vital details. This not only aids in the tracking and distribution of medications but also helps to prevent errors in administration.

Lastly, the packaging process is also integrated into the Automatic Syringe Equipment Filling Assembly Machine, allowing for a fully automated end-to-end production line. This integration reduces the need for manual intervention, minimizes the risk of human error, and ensures that each syringe is packaged securely and ready for distribution.

The Automatic Syringe Equipment Filling Assembly Machine's online detection capabilities are another testament to its cutting-edge technology. By continuously monitoring the production process, the machine can identify and correct any issues in real time, reducing waste and improving overall production quality.

As the pharmaceutical industry continues to evolve, the Automatic Syringe Equipment Filling Assembly Machine stands as a beacon of innovation, offering a solution that meets the growing needs of precision medicine. Its integration of multiple processes into one machine not only streamlines production but also sets a new standard for quality and efficiency in the manufacture of injectable drugs.

In conclusion, the Automatic Syringe Equipment Filling Assembly Machine is more than just a machine; it is a symbol of the future of pharmaceutical production. With its ability to handle a multitude of tasks with unparalleled accuracy and efficiency, this machine is poised to change the landscape of the industry, ensuring that patients receive the quality medications possible.

English

English русский

русский Español

Español