China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

In recent years, the medical manufacturing sector has witnessed a noticeable shift toward automation, driven by the increasing global demand for syringes. As vaccines, insulin injections, and oral medications become more widely used, the need for efficient, scalable, and consistent syringe production is growing rapidly. One piece of equipment standing at the center of this transformation is the Automatic Syringe Filling Production Assembly Machine.

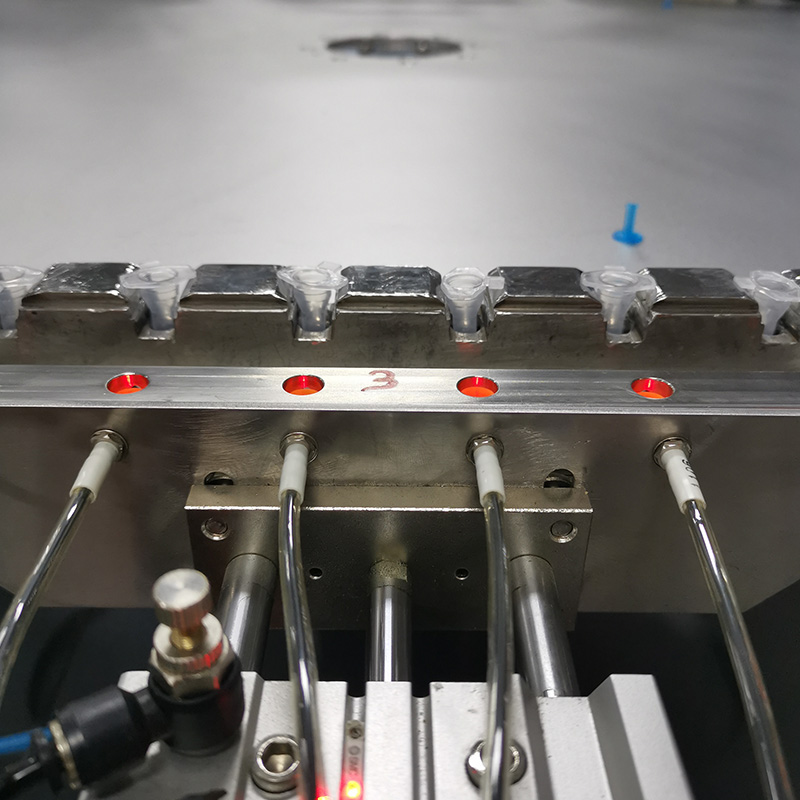

The Automatic Syringe Filling Production Assembly Machine plays a vital role in the pharmaceutical and healthcare packaging industry by offering streamlined production processes. These machines integrate syringe loading, fluid filling, piston insertion, labeling, and packaging into a continuous, automated operation. As a result, manufacturers are turning to this technology to meet surging production requirements while maintaining product quality and hygiene standards.

Demand Fueled by Vaccine and Insulin Supply Chains

The global vaccine rollout in recent years, along with the rising incidence of diabetes worldwide, has significantly increased the use of disposable and prefilled syringes. Consequently, companies involved in the manufacturing of these syringes are seeking ways to improve their throughput and minimize labor dependency. This has led to a notable uptick in the adoption of the Automatic Syringe Filling Production Assembly Machine across North America, Europe, Asia, and emerging healthcare markets.

These machines ensure accurate fluid dosing, consistent assembly, and reduced contamination risk. As product integrity is essential in pharmaceutical applications, the Automatic Syringe Filling Production Assembly Machine provides the precision and process control necessary to meet regulatory standards without excessive reliance on manual labor.

Reducing Human Error and Improving Production Efficiency

In syringe manufacturing, any inconsistency or error in filling volume, sealing, or labeling can to costly product recalls or safety concerns. With the introduction of the Automatic Syringe Filling Production Assembly Machine, companies can reduce the probability of such errors. The automated workflow not only increases daily output but also improves the uniformity of syringe filling and assembly processes.

Manufacturers using the Automatic Syringe Filling Production Assembly Machine report smoother operations and faster production cycles compared to manual or semi-automated methods. The machines are designed to handle different syringe types, including oral, luer-lock, and prefilled variants, offering adaptability in a competitive and regulated industry.

Expanding Adoption Across Manufacturing Hubs

China has emerged as a significant production base for the Automatic Syringe Filling Production Assembly Machine, with several companies exporting their systems globally. These machines are often modular, allowing pharmaceutical firms to select specific configurations based on production volume, liquid type, and packaging requirements.

In Europe and the United States, medical device manufacturers are increasingly investing in automated syringe lines as part of their long-term capacity planning. The Automatic Syringe Filling Production Assembly Machine is viewed not only as a productivity tool but also as an essential step toward complying with Good Manufacturing Practice (GMP) regulations.

Responding to Future Healthcare Needs

As healthcare systems prepare for future demands, especially with the rise of preventive medicine and personalized therapies, the role of the Automatic Syringe Filling Production Assembly Machine is expected to expand. The ability to deliver sterile, prefilled syringes at scale supports both public health objectives and the operational needs of pharmaceutical companies.

Furthermore, as production facilities seek to balance cost-efficiency with regulatory compliance, the Automatic Syringe Filling Production Assembly Machine offers a solution that can evolve with industry trends. Modular systems, remote monitoring capabilities, and compatibility with various fluid viscosities make these machines suitable for a wide range of applications.

The growing global demand for vaccines, insulin, and other injectable or oral medications is placing pressure on manufacturers to increase their syringe output while maintaining consistency and quality. The Automatic Syringe Filling Production Assembly Machine has emerged as a key technology to support this expansion, offering reliable, automated solutions that meet the requirements of modern pharmaceutical manufacturing.

As companies continue to scale their operations, the importance of the Automatic Syringe Filling Production Assembly Machine will only become more evident. Its role in enhancing production efficiency, ensuring product integrity, and supporting regulatory compliance marks it as a critical asset in today’s evolving healthcare landscape.

English

English русский

русский Español

Español