China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

As the demand for high-quality medical consumables continues to grow, medical device manufacturers are under increasing pressure to improve both production efficiency and product reliability. One technology making a significant impact in this space is the Automatic Needle Syringe Inspection Manufacturing Assembly Machine. This integrated solution combines syringe assembly, real-time visual inspection, defect elimination, coding, and labeling—all within a single, highly automated production system.

The Automatic Needle Syringe Inspection Manufacturing Assembly Machine is designed to meet the growing needs of manufacturers seeking to upgrade their production lines. It enables the complete assembly of needle syringes, starting from component loading to finished product packaging, while incorporating intelligent quality control mechanisms throughout each step. This all-in-one solution is rapidly becoming a cornerstone in the modernization of syringe manufacturing for both domestic and export markets.

At the core of its value, the Automatic Needle Syringe Inspection Manufacturing Assembly Machine significantly reduces manual intervention. By automating labor-intensive processes, the machine enhances productivity, minimizes human error, and ensures consistent product quality. For companies striving to meet regulatory standards and deliver reliable products to hospitals and clinics, this machine provides a critical edge.

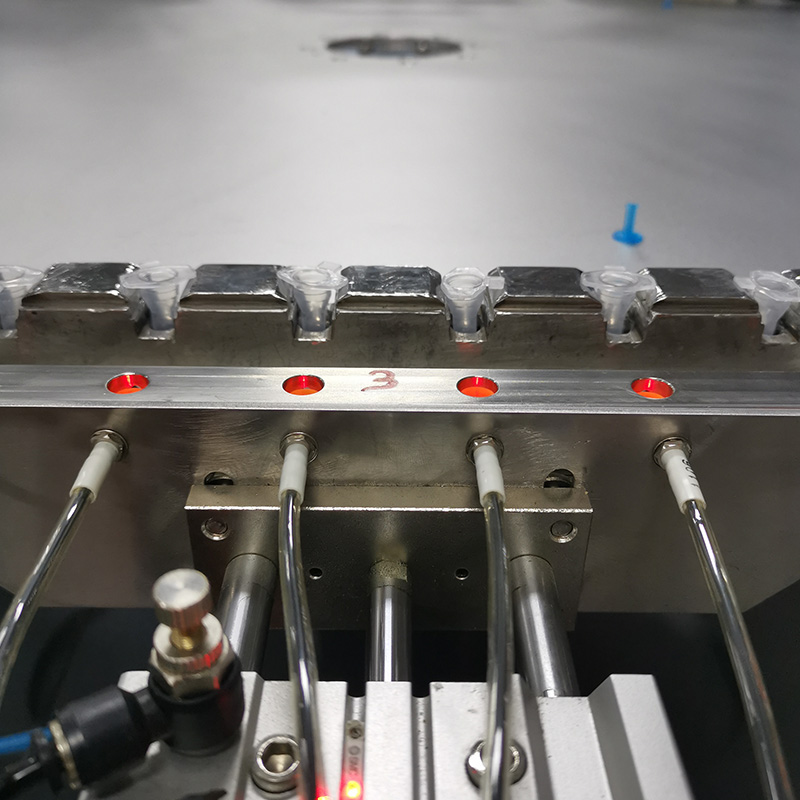

One of the standout features of the Automatic Needle Syringe Inspection Manufacturing Assembly Machine is its advanced real-time visual inspection system. Integrated high-resolution cameras and sensors detect microscopic defects in syringe barrels, plungers, needle alignment, and assembly integrity. This built-in quality assurance mechanism enables manufacturers to identify and reject defective items on the spot, greatly improving overall yield and reducing the risk of defective products reaching end users.

Another core functionality of the Automatic Needle Syringe Inspection Manufacturing Assembly Machine is its precise and reliable coding and labeling system. Whether required for traceability, regulatory compliance, or inventory control, the machine supports high-speed inkjet or laser marking, along with automated label application. This ensures that every syringe is properly marked with batch numbers, expiration dates, and other necessary information.

The Automatic Needle Syringe Inspection Manufacturing Assembly Machine also supports seamless integration with MES (Manufacturing Execution System) platforms. This allows manufacturers to capture production data in real time, monitor performance metrics, and optimize operational workflows. Such connectivity helps medical device companies align with industry 4.0 initiatives and move toward fully digitalized manufacturing environments.

Medical factories upgrading their automation lines report significant benefits from deploying the Automatic Needle Syringe Inspection Manufacturing Assembly Machine. These include shortened production cycles, improved defect detection rates, enhanced traceability, and reduced labor costs. Additionally, the machine’s modular design allows for easy reconfiguration to accommodate different syringe sizes or assembly standards, offering operational flexibility in fast-changing healthcare markets.

With rising global awareness around injection safety and increasing regulatory scrutiny, the role of the Automatic Needle Syringe Inspection Manufacturing Assembly Machine is becoming even more critical. It supports compliance with international standards such as ISO 13485, CE MDR, and FDA requirements, enabling companies to access global markets with confidence.

The Automatic Needle Syringe Inspection Manufacturing Assembly Machine is not only an investment in machinery—it is a strategic move toward smarter, safer, and more efficient medical device manufacturing. As healthcare systems place greater importance on product quality and supply reliability, the machine is poised to become a standard feature in next-generation medical production facilities.

In conclusion, the Automatic Needle Syringe Inspection Manufacturing Assembly Machine represents a transformative solution for medical device companies aiming to modernize their syringe production lines. Through its advanced automation, quality assurance, and seamless integration capabilities, it delivers the performance needed to thrive in a competitive and quality-driven industry.

English

English русский

русский Español

Español