China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

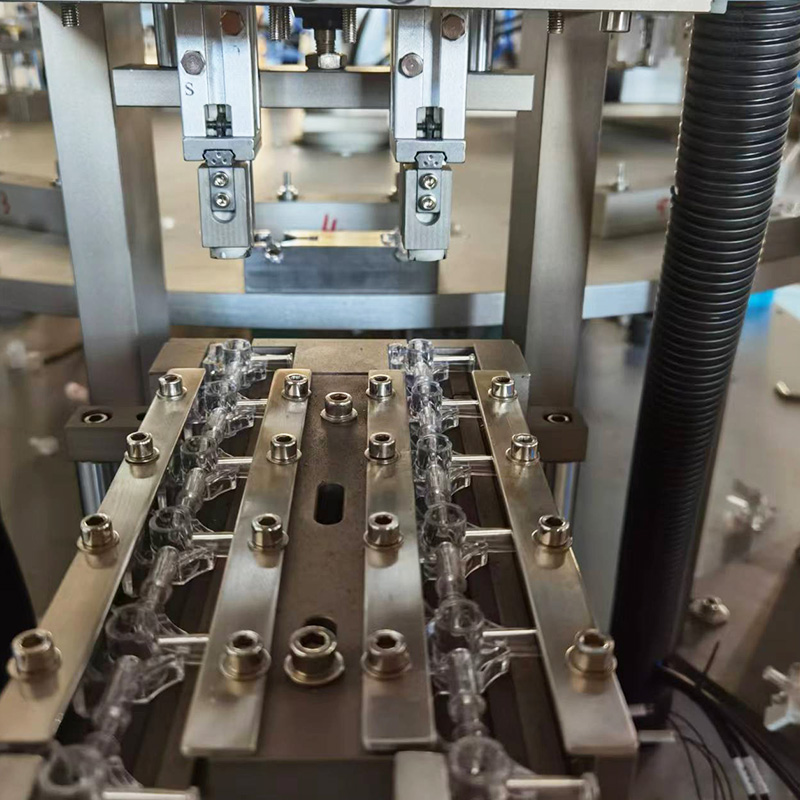

The demand for medical three-way valves has been steadily growing due to the increasing use of medical devices, infusion systems, and respiratory equipment. To meet this expanding need, manufacturers are turning to advanced production solutions. A Fully Automated Production Line for Medical Three-Way Valves provides a reliable method to produce these components in a consistent and scalable manner, supporting the requirements of the healthcare sector.

Applications in Medical Devices

Medical three-way valves are essential components in various medical devices. In infusion systems, these valves help control the flow of fluids accurately, ensuring patient safety and proper administration of medications. Respiratory equipment also relies on three-way valves to direct airflow and manage gas mixtures. Other applications include dialysis machines, anesthesia systems, and laboratory equipment, where reliable valve operation is crucial. The use of a Fully Automated Production Line for Medical Three-Way Valves ensures that each valve is manufactured according to the required specifications, supporting the functionality of these critical devices.

Market Demand for Medical Three-Way Valves

The medical industry is experiencing a rise in demand for three-way valves, driven by the expansion of hospitals, clinics, and home healthcare services. As more medical devices are deployed, the need for components that can be produced in larger quantities without compromising consistency has increased. A Fully Automated Production Line for Medical Three-Way Valves addresses this need by allowing manufacturers to scale production to match market demand. This type of production line also supports standardization, which is important for ensuring compatibility across different medical systems and devices.

Meeting the Needs of a Growing Healthcare Market

Healthcare facilities require a steady supply of components to maintain uninterrupted service. The adoption of a Fully Automated Production Line for Medical Three-Way Valves allows manufacturers to respond to orders in a timely manner, reducing potential delays in device assembly or delivery. By automating the production process, manufacturers can maintain uniformity in each batch of valves, which is important for maintaining reliability and consistency in medical devices.

Flexibility and Adaptability

Another important aspect of a Fully Automated Production Line for Medical Three-Way Valves is its ability to adapt to different production requirements. Depending on the type of valve or the specifications requested by customers, the production line can be configured to handle variations in design, size, and materials. This flexibility helps manufacturers respond to changes in the healthcare market, such as increased demand for certain devices or regional variations in medical standards.

Supporting Healthcare Growth

As the healthcare industry continues to expand, the demand for essential components like three-way valves will likely increase. A Fully Automated Production Line for Medical Three-Way Valves provides a solution that supports consistent production volumes and quality, enabling manufacturers to meet the needs of hospitals, clinics, and medical device companies. By ensuring a steady supply of reliable valves, the production line contributes to the overall efficiency and reliability of healthcare services.

The growing use of medical devices, infusion systems, and respiratory equipment has led to increased demand for medical three-way valves. A Fully Automated Production Line for Medical Three-Way Valves offers a practical solution to meet this market need, providing a production process that is consistent, scalable, and adaptable. By supporting the supply of these critical components, automated production lines help manufacturers respond to the expanding requirements of the healthcare industry while maintaining reliability in each batch of valves.

English

English русский

русский Español

Español