China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

The medical device industry is undergoing a significant transformation with the increasing adoption of Needle-Free IV Connectors Assembly Machines. These advanced systems are reshaping the production of Needleless Infusion Device Assembly Machines, ensuring safer, more efficient, and cost-effective manufacturing processes. As healthcare facilities worldwide prioritize infection prevention and ease of use, the demand for Needle-Free IV Connectors Equipment Assembly Machines continues to rise, driving innovation in automation and quality control.

The Growing Importance of Needle-Free IV Connectors

Needle-free IV connectors are critical components in modern infusion therapy, designed to reduce needlestick injuries, minimize infection risks, and improve workflow efficiency in hospitals. Unlike traditional needle-based systems, these connectors allow healthcare providers to administer medications and fluids without repeated needle insertions, enhancing patient and clinician safety.

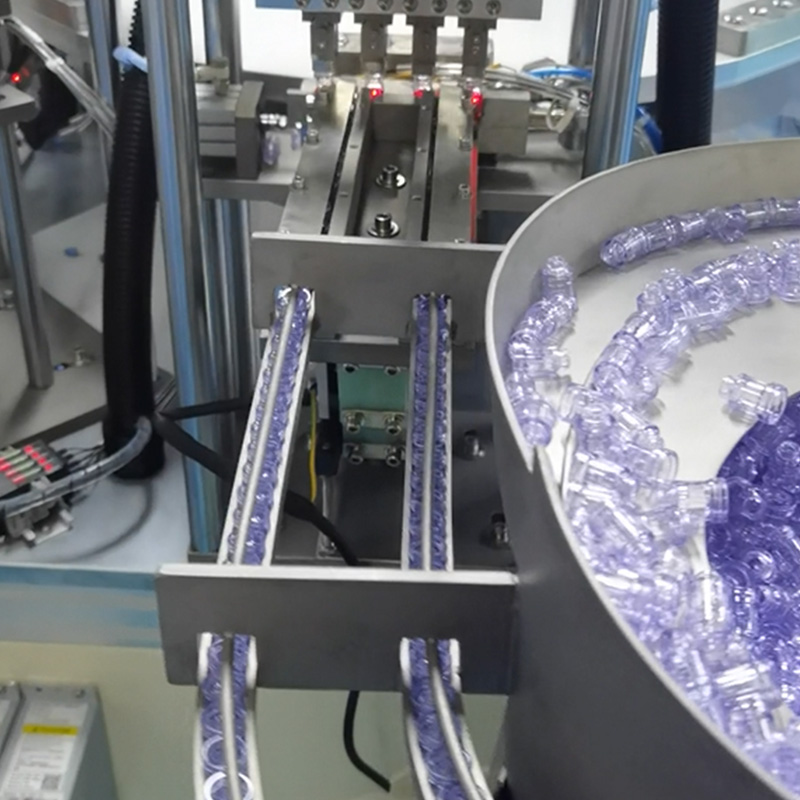

To meet the rising demand, manufacturers are investing in high-precision Needle-Free IV Connectors Assembly Machines that streamline production while maintaining strict sterility standards. These machines automate the assembly of key components such as valves, housings, and sealing mechanisms, ensuring consistent quality in Needleless Infusion Device Assembly Machines.

Technological Advancements in Assembly Machines

Recent innovations in Needle-Free IV Connectors Equipment Assembly Machines include

1. Automated Precision Assembly

Modern assembly machines utilize robotics and computer vision to align and secure tiny components with micron-level accuracy. This automation reduces human error and increases production speed, making Needleless Infusion Device Assembly Machines more efficient than ever.

2. Sterility Assurance Systems

Since IV connectors must meet stringent sterility requirements, advanced assembly machines incorporate cleanroom-compatible designs, UV sterilization, and particulate monitoring to prevent contamination.

3. AI-Powered Quality Control

Artificial intelligence (AI) and machine learning are being integrated into Needle-Free IV Connectors Assembly Machines to detect defects in real time. High-resolution cameras and sensors inspect each unit for leaks, misalignments, or material flaws, ensuring only compliant products reach the market.

4. Modular and Scalable Production Lines

Manufacturers are adopting flexible assembly systems that can be reconfigured for different connector designs. This adaptability allows companies to quickly respond to changing market demands without major retooling.

Market Growth and Industry Trends

The global needle-free IV connectors market is expanding rapidly, driven by

Increasing Hospital-Acquired Infection (HAI) Concerns— Healthcare providers are shifting to needle-free systems to reduce bloodstream infections.

Regulatory Push for Safer Devices—Agencies like the FDA and EMA encourage needle-free technologies to protect medical staff from needlestick injuries.

Rising Chronic Disease Prevalence—More patients requiring long-term IV therapy are benefiting from needle-free solutions.

To keep up with demand, manufacturers are scaling up production using high-speed Needle-Free IV Connectors Equipment Assembly Machines. Emerging markets, particularly in Asia and Latin America, are investing in localized production to improve supply chain resilience.

Sustainability and Cost Efficiency

As healthcare systems seek cost-effective solutions, Needleless Infusion Device Assembly Machines are being optimized for energy efficiency and material conservation. Some key developments include

Reduced Material Waste—Precision assembly minimizes excess plastic and metal usage.

Energy-Efficient Motors—Newer machines consume less power without compromising output.

Recyclable Packaging Integration—Some assembly lines now include eco-friendly packaging processes.

These improvements help manufacturers lower production costs while meeting sustainability goals—a growing priority for medical device companies.

Future Outlook and Industry Collaboration

The future of Needle-Free IV Connectors Assembly Machines lies in smarter, more connected production systems. Key trends to watch include

IoT-Enabled Machines—Remote monitoring and predictive maintenance will reduce downtime.

3D Printing Integration—Additive manufacturing may allow for rapid prototyping of new connector designs.

Collaboration with Healthcare Providers—Feedback from clinicians will drive further ergonomic and functional improvements.

Regulatory bodies are also expected to introduce stricter guidelines for needle-free connector manufacturing, ensuring patient safety remains a top priority.

The evolution of Needle-Free IV Connectors Assembly Machines is playing a pivotal role in modern healthcare, enabling safer, more efficient infusion therapies. With advancements in automation, AI, and sustainability, manufacturers of Needleless Infusion Device Assembly Machines are well-positioned to meet global demand while maintaining the quality standards.

As technology continues to progress, these machines will further enhance the production of Needle-Free IV Connectors Equipment, ensuring that healthcare providers have access to reliable, infection-preventing solutions. The industry’s commitment to innovation and safety promises a future where needle-free IV systems become the universal standard in infusion therapy.

English

English русский

русский Español

Español