China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

As demand for medical devices continues to grow, manufacturers are increasingly looking for production solutions that can scale efficiently without compromising on quality. One question that often comes up is: how can syringe producers expand their output in a sustainable way? The answer may lie in adopting a Fully Automated Production Line for Syringes.

But what does "scalability" really mean in this context? Essentially, it refers to the ability of a production system to handle increased volume or adapt to new product designs without requiring fundamental redesigns or excessive downtime. A Fully Automated Production Line for Syringes is specifically engineered for this kind of flexibility.

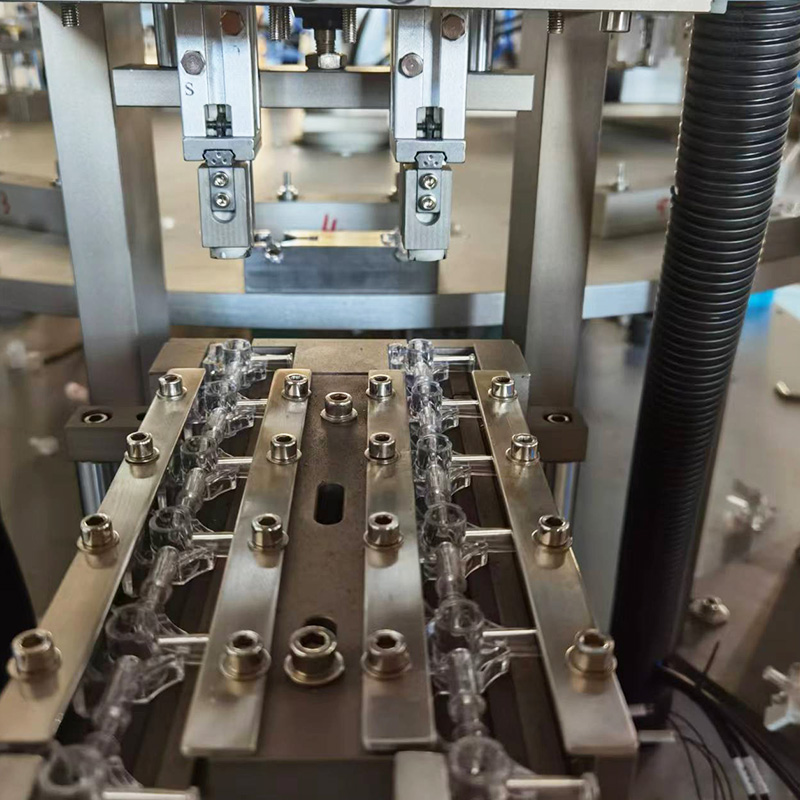

A key advantage of such a system is its modular architecture. Much like the automated assembly systems used for producing urine bag valves, a Fully Automated Production Line for Syringes can be configured or reconfigured to accommodate different syringe sizes, materials, or assembly processes. This means that as demand grows or product lines diversify, the same production platform can remain in use, protecting long-term investment.

Another aspect users are curious about is integration. Can a new automated line work alongside existing equipment? In mass cases, yes. A Fully Automated Production Line for Syringes is designed with compatibility in mind. Standard communication protocols and adjustable mechanical interfaces allow it to merge smoothly into current factory layouts. This reduces transition time and avoids operational disruption.

How does automation help maintain consistency when scaling up? Traditional manual assembly is vulnerable to variability—especially when production increases. In contrast, a Fully Automated Production Line for Syringes performs repeated tasks with high precision. Every movement, every component placement, and every inspection is controlled programmatically.

Let's talk about human resources. Scaling production often requires hiring and training more operators—a process that is both time-consuming and costly. With a Fully Automated Production Line for Syringes, one or a few technicians can oversee multiple processes. Automated handling, vision-assisted inspection, and robotic sorting reduce dependency on large manual labor teams. This not only controls labor costs but also human-induced errors.

What about downtime during capacity expansion? This is a valid concern. The modularity of a Fully Automated Production Line for Syringes allows for phased implementation. Manufacturers can start with a baseline configuration and add modules as needed—for example, extra assembly units, testing stations, or packaging systems. This step-by-step approach helps maintain production continuity during upgrades.

Energy and operational cost are also frequently raised topics. A well-designed Fully Automated Production Line for Syringes prioritizes energy efficiency. Many systems operate within a power range of 1.8–2.0 kW and use compressed air economically. These features help keep operational expenses manageable even when running at higher capacities.

In a sector where product integrity is critical, automation supports traceability and assurance. Each syringe produced on a Fully Automated Production Line for Syringes can be tracked and tested automatically. Data logs provide insights into production trends, which help in continuous improvement and compliance with medical industry standards.

A Fully Automated Production Line for Syringes provides not just higher output, but smarter growth. It enables manufacturers to respond confidently to increasing market demands while maintaining product and operational efficiency.

English

English русский

русский Español

Español