China Zhejiang Taizhou Ambe Trading Co., Ltd. is a manufacturer specializing in the production of medical equipment automation equipment.

In recent years, automation has played a pivotal role in transforming the medical manufacturing sector, particularly in the area of consumable production. Among the technologies gaining recognition is the Folding Dialysis Paper Filter Paper Automatic Rolling Machine, a specialized device designed to streamline the preparation and processing of dialysis filter paper. This machine is becoming increasingly important as healthcare providers demand higher volumes of reliable and sterile filtration materials.

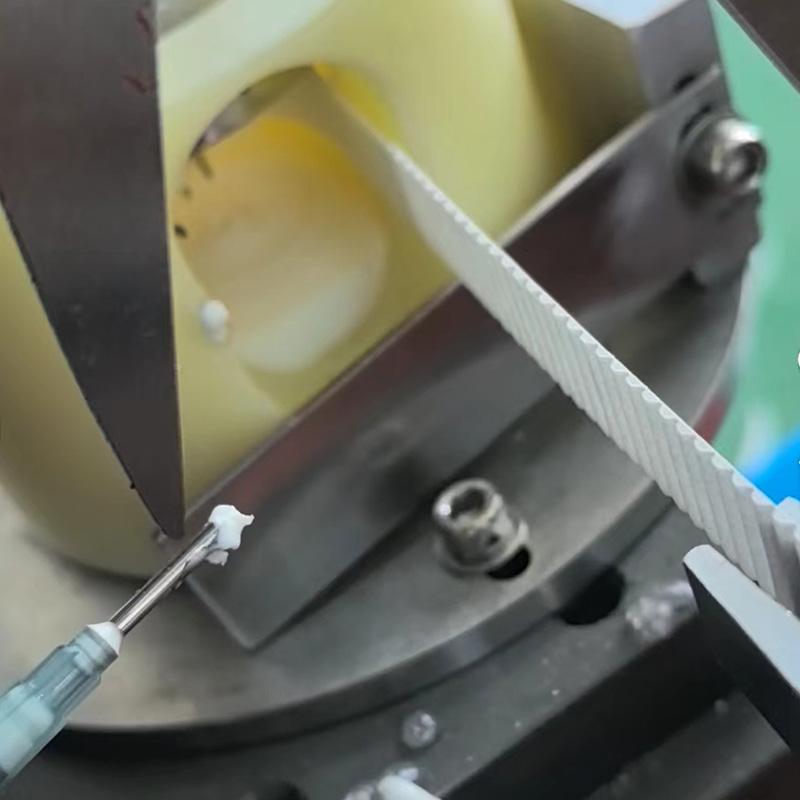

The Folding Dialysis Paper Filter Paper Automatic Rolling Machine is engineered to automate the folding, aligning, and rolling of dialysis paper used in a variety of medical filtration systems. These include hemodialysis cartridges, medical-grade filters, and fluid purification units. By handling the filtration media with consistent tension and alignment, the Folding Dialysis Paper Filter Paper Automatic Rolling Machine ensures that each roll is manufactured to meet strict quality and hygiene standards required in clinical applications.

One of the major benefits of the Folding Dialysis Paper Filter Paper Automatic Rolling Machine is its ability to eliminate manual handling, which can introduce variability and contamination risks. Instead, the machine uses precision rollers, folding modules, and guiding systems to fold the dialysis paper into the desired shape and density before rolling it uniformly. This level of consistency is essential in medical environments, where even minor deviations in filter quality can impact patient safety.

The Folding Dialysis Paper Filter Paper Automatic Rolling Machine supports high-speed operations, allowing manufacturers to scale up production to meet growing demand. With adjustable settings, the machine can process various types and thicknesses of dialysis paper, offering flexibility for manufacturers who produce different filtration products. This adaptability makes the Folding Dialysis Paper Filter Paper Automatic Rolling Machine a valuable asset in both large-scale factories and smaller medical device workshops.

Another important feature of the Folding Dialysis Paper Filter Paper Automatic Rolling Machine is its integration with digital monitoring systems. Modern machines are equipped with touchscreen interfaces, real-time error detection, and automated shut-off features to ensure operational safety. Operators can monitor paper tension, folding speed, and roll diameter, ensuring that each batch meets specified parameters.

In terms of maintenance, the Folding Dialysis Paper Filter Paper Automatic Rolling Machine is designed with accessibility in mind. Components are modular, which simplifies routine inspections and part replacements. Many machines also come with diagnostic tools that alert users to maintenance needs before any disruption occurs.

From a cost-efficiency perspective, the Folding Dialysis Paper Filter Paper Automatic Rolling Machine helps reduce material waste and improve throughput. Its automated feeding and alignment systems minimize the chance of paper misalignment or tearing, which is particularly valuable when working with delicate dialysis filter materials. This leads to more usable output and lower overall production costs.

Manufacturers looking to improve compliance with international standards also benefit from the Folding Dialysis Paper Filter Paper Automatic Rolling Machine. The machine can be calibrated to align with ISO and GMP requirements, ensuring that the output meets the regulatory expectations for medical consumables. With quality assurance built into each phase of production, the Folding Dialysis Paper Filter Paper Automatic Rolling Machine enhances both process integrity and product traceability.

As healthcare systems worldwide continue to expand access to dialysis and other filtration-based therapies, the demand for high-quality dialysis paper will grow. In this context, the Folding Dialysis Paper Filter Paper Automatic Rolling Machine is expected to become a core part of the medical manufacturing process. Its precision, efficiency, and adaptability position it as a reliable solution for companies committed to innovation and consistent product quality.

In conclusion, the Folding Dialysis Paper Filter Paper Automatic Rolling Machine represents a significant advancement in the automation of medical filter paper production. Its contribution to product consistency, manufacturing speed, and operational safety makes it an essential tool in the evolving medical industry landscape."

English

English русский

русский Español

Español